Siemens Digital Industries Software announced today that skyTran, developer of a personal rapid transit system taking aim at the world of gridlocked traffic, is using software from the Siemens Xcelerator portfolio to develop and manufacture a new maglev transport system. Using Simcenter MAGNET software, skyTran reduced physical prototyping costs by 90 percent.

Founded in 2011 and now a NASA Space Act company, skyTran is headquartered in Huntington Beach, California. skyTran is a high-capacity, personal mass transit system and its on-demand, personal occupancy vehicles allow riders and cargo to travel above the road at motorway speeds and beyond. Vehicles operate autonomously and use proprietary switching technology to safely navigate complex guideway networks direct-to-destination without the constraints of ground-based corridors.

Founded in 2011 and now a NASA Space Act company, skyTran is headquartered in Huntington Beach, California. skyTran is a high-capacity, personal mass transit system and its on-demand, personal occupancy vehicles allow riders and cargo to travel above the road at motorway speeds and beyond. Vehicles operate autonomously and use proprietary switching technology to safely navigate complex guideway networks direct-to-destination without the constraints of ground-based corridors.

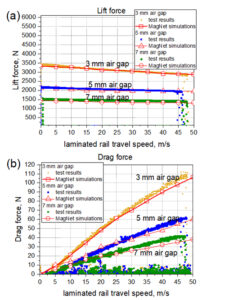

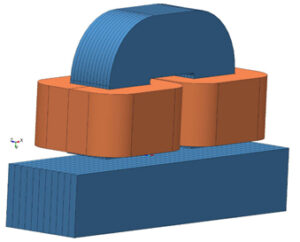

The system uses a modified and improved maglev variant called electrodynamic suspension based on coupled levitation and propulsion systems. skyTran’s propulsion system uses a drive motor with a magnetic rotor and aluminum stator. In contrast, the levitation system uses the electromagnets in the vehicle and their interaction with the steel guideways.

To develop this revolutionary transport system, skyTran has a full-scale test rig, but each test takes a lot of time and cost. Additionally, it can be difficult to visualize what’s happening in the physical system while it is operating. Gaining further insight necessitated adding sensors but these can influence the results from the test rig. To overcome this, the team wanted a simulation solution that could help reduce the scale of the test rig program and interrogate the test in new, faster and cheaper ways. skyTran chose Simcenter MAGNET from the Siemens Xcelerator portfolio to help them confront these issues.

– By using Simcenter MAGNET we can speed up the manufacturing of the parts and building the test fixture process by four times compared to when we don’t do any simulation, says Iana Volvach, Finite Elements Analysis Engineer, skyTran. In terms of the cost, we can save a lot since we don’t buy the parts to create every single experiment and the test  fixture for it. When modeling with Simcenter MAGNET we can reduce the cost spent on prototypes by 90 percent compared to when no simulation is used.

fixture for it. When modeling with Simcenter MAGNET we can reduce the cost spent on prototypes by 90 percent compared to when no simulation is used.