As automation and Industry 4.0 take the manufacturing world by storm, multiaxis machining is becoming a common topic of discussion in shops globally. The reason? Multiaxis machining enables faster, more complex machining with less human labor.

What is Multiaxis Machining?

Traditional milling has been around for over 200 years, but 3-axis milling was not invented until 1861, when Brown & Sharpe created the Universal Milling Machine. This machine, as with all traditional 3-axis milling machines, could move in three linear directions. Machining was made even more efficient in the 1950s with the debut of numerical control machining.

The latest technological innovation, multiaxis machining, expands on the traditional 3-axis machine’s motion abilities. Instead of moving along three simple linear axes, multiaxis machines can move in four or more directions by adding rotary axes and parallel linear axes. Some modern multiaxis centers can use nine axes, but most use only four or five.

How do Multiaxis Machines Work?

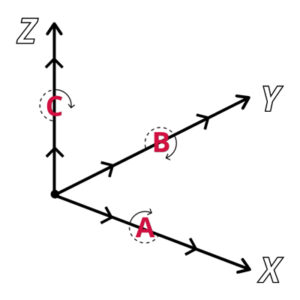

The three axes of a traditional vertical 3-axis machine are X, Y, and Z: left-right, towards-away, and up-down. Most 3-axis milling centers have a stationary table and a moving cutter that travels along these three axes; sometimes the cutter only travels along the Z-axis while the table travels along the X- and Y-axes. This particular style of machining is great for simpler actions like drilling holes and cutting edges.

4-axis machines operate on all three of the traditional axes – X, Y, and Z – as well as an additional axis: the A-axis (rotation around the X-axis) or the B-axis (rotation around the Y-axis). 5-axis machines operate on X-, Y-, Z-, A-, and B-axes. Multiaxis machines can progress to using nine axes: the linear axes (X, Y, and Z), the rotary axes (A, B, and C – which rotates around the Z-axis), and the parallel linear axes (U, V, and W). The parallel linear axes move along the X, Y, and Z directions. Consider a quill on a vertical machine: the head would be moved up and down in the Z direction, but the quill’s up-and-down motion would be controlled with a W-axis. In multiaxis operations, the machine tool’s four to nine axes are all involved simultaneously. Imagine holding a part in your hand. If you were a 3-axis machine, you could only move the part up, down, left, right, towards you, and away from you. If you were a 4-axis machine, you could move the part in all of those directions while also tipping it from left to right. If you were a 5-axis machine, you could add tipping the part forward and backward to your repertoire, and so on.

Multiaxis Machining Applications

Any shop can benefit from multiaxis techniques. Because the tool cutter can move along so many axes, multiaxis machining can allow complete machining with only one setup and with shorter tools. There is no need to have an operator standby to remove and set up the part over and over. With this ability comes a plethora of time and money-saving results—fewer chances for user error during setup, fewer hours required, decreased lead time, high repeatability, and better interface with Industry 4.0. Multiaxis machining also improves surface finishes as the tool moves tangentially across the part’s surface.

Multiaxis machining is inherently more powerful than 3-axis machining, but each type has its own advantages. For parts that only need to have holes drilled in their sides or around their perimeter, 4-axis machining might be enough for single setup machining. For parts that are more intricate, like medical pieces with tilted surfaces and aerospace parts with complex geometries and tight tolerances, machining with five or more axes might be necessary.

Here are the industries that commonly use multiaxis machining:

- Aerospace

- Defense

- Medical

- Energy

- Automotive

Advantages of Using Mastercam Multiaxis

Mastercam’s Multiaxis is a powerful 4- and 5-axis solution that can work in conjunction with Mastercam Mill 3D, Mastercam Router 3D, Mastercam Mill-Turn, and Mastercam for SOLIDWORKS. This product maintains stock model awareness, a 5-axis safe zone around the machined part, and tilt axis limits on the tool angle to avoid violating machine limits for the safest machining possible. It also comes with Dynamic Motion technology for outstanding multisurface roughing and finishing. The abilities of Multiaxis, which range from standard to advanced, give users complete control over cut pattern, tool axis, and collision avoidance.

Cut Patterns, ranging from simple 2D wireframes to complex multisurface grids, guide the cutting along predetermined paths. These varied toolpaths optimize cutting while ensuring safety.

Tool Axis Control gives users the ability to specify tool axis, lead/lag, entry/exit, and tilt. This technology orients the tool’s center axis as it follows the cut pattern, and it uses advanced gouge checking and a 5-axis safe zone during machining to protect the part.

Collision Control provides a “near miss tolerance” field so that users can choose exactly how close they want to allow the tool to approach any workholding or machining component.

Mer info: AME: 031-411 700, www.ameab.se