Siemens technology ensures efficient processes in the food and pharmaceutical industries

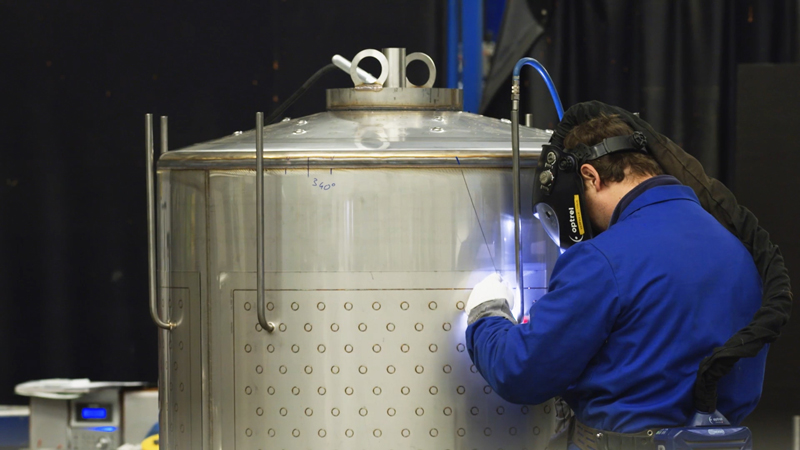

Diksmuide, Belgium. Packo Inox NV (Packo) manufactures high-quality stainless steel systems for hygienesensitive production processes in the food and pharmaceutical industries. In addition to individual system components, the company also supplies complete process lines. On the one hand, a high degree of standardization is important to ensure easy integration into existing systems. On the other, the system modules have to be optimized to meet specific customer requirements. To this end, Packo has relied for years on a close collaboration with Siemens to ensure reliable development of its systems. In addition to QR coding with Siemens solutions for easy documentation and integration of system modules, Packo also benefits from robust components with high reliability, and highly accurate process instrumentation.

The equipment developed by Packo must be able to cope with harsh industrial environments and to be integrated into higher-level systems. To this end, Siemens uses QR (Quick Response) coding to allow access to its measuring devices’ technical information. This simplifies subsequent transfer of documentation as well as the integration of devices into third-party subsystems. Another area in which Siemens technology is used is Packo’s CIP (Cleaning in Place) systems. Tanks, pipes, heat exchangers, and other elements are automatically cleaned without even having to open or disassemble the components.

The equipment developed by Packo must be able to cope with harsh industrial environments and to be integrated into higher-level systems. To this end, Siemens uses QR (Quick Response) coding to allow access to its measuring devices’ technical information. This simplifies subsequent transfer of documentation as well as the integration of devices into third-party subsystems. Another area in which Siemens technology is used is Packo’s CIP (Cleaning in Place) systems. Tanks, pipes, heat exchangers, and other elements are automatically cleaned without even having to open or disassemble the components.

Robust, reliable technology

Packo relies on Siemens process instrumentation solutions for reliable monitoring of temperature, and other process parameters. This includes the Sitrans F M MAG 6000 for measuring the flow, the analog Sitrans P compact pressure transducer, and the Sitrans TS300 for measuring temperature. What all products taken from the Sitrans portfolio have in common is that they can cope with high temperatures and the occasionally aggressive cleaning chemicals for years on end.

Fully automated processes

The cleaning processes – water prestage, hot detergent and water/steam main cycle, followed by cold water – all run completely automatically. Which system components are cleaned, for how long, and with what, or the dosage of cleaning agent are also controlled by Siemens automation components. The same applies to the control, operation, and monitoring of the systems. Packo also supplies dispensing units and storage tanks in addition to CIP systems, relying always on Siemens’ easy-to-integrate and efficient solutions.