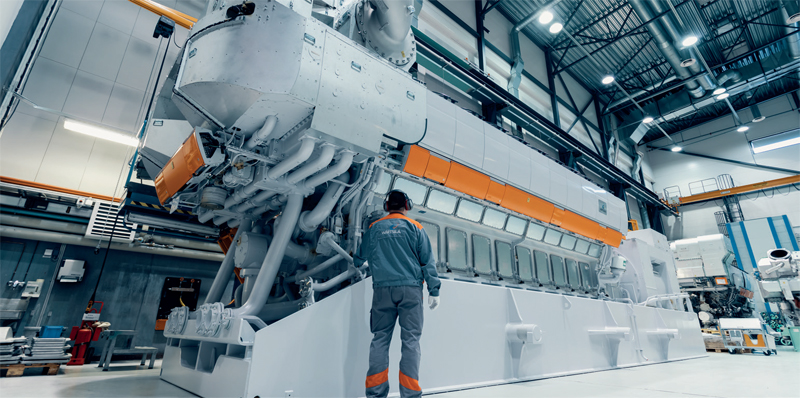

Marine engine manufacturer uses Siemens solutions to design one of the world’s most efficient diesel engines

The maritime industry is a staple of the global economy: around 90 percent of the world’s trade involves shipping, while the cruise and leisure industry is a growing revenue generator. Shipping is recognized as the most efficient form of commercial transport, with the lowest carbon dioxide (CO2) emissions per metric ton of cargo transported. The enormous scale of the industry, however, means that it is still a significant contributor to the world’s CO2 emissions.

The maritime industry is working diligently to reduce environmental impact with new, stricter emissions regulations. Ship manufacturers and engine designers need to respond quickly to these rules with new, efficient, designs. Wärtsilä is one of the world’s largest ship engine manufacturers and servicing agents in the world – the company services or powers one in three ships. As a result, Wärtsilä is in a constant state of innovation and development to maintain their standing as an industry leader. The company is committed to sustainability, with an overriding focus on ensuring profitability, providing environmentally sound products and services and ensuring responsible business conduct.

The Wärtsilä 31 diesel engine, released in 2015, was named the most efficient diesel engine by Guinness World Records. The engine’s diesel fuel consumption is as low as 165 grams per kilowatt hour (g/kWh), significantly lower than any other 4-stroke diesel engine on the market. Its exceptional fuel efficiency is made possible through the use of new technologies such as 2-stage turbocharging, a high-pressure fuel injection system and adjustable valve actuation, in combination with the next-generation engine control system.

The Wärtsilä 31 diesel engine, released in 2015, was named the most efficient diesel engine by Guinness World Records. The engine’s diesel fuel consumption is as low as 165 grams per kilowatt hour (g/kWh), significantly lower than any other 4-stroke diesel engine on the market. Its exceptional fuel efficiency is made possible through the use of new technologies such as 2-stage turbocharging, a high-pressure fuel injection system and adjustable valve actuation, in combination with the next-generation engine control system.

Lars Ola Liavåg, manager of the thermofluids and simulations team at Wärtsilä, says Simcenter STAR-CCM+ software, the multidisciplinary design simulation tool from Siemens Digital Industries Software, helped the company create this innovative engine.

The Wärtsilä 31 is a medium speed 4-stroke engine, designed for use as either a main propulsion engine or an auxiliary engine. It can run as either a diesel, dual-fuel or spark-ignited gas engine. Development began in 2010 and took five years to complete. Liavåg and his team were involved from the earliest part of the engine design process.

– We knew our customer requirements from internal stakeholders, so we aimed to make a new engine to replace existing models but also benefit new customers,” says Liavåg.

The new design had to be fuel efficient and meet all regulatory requirements. Wärtsilä also decided to use a modular design, making it easier to change parts and assemblies; small size modular engines have long been in use, but no other engine of this size uses a similar modular approach.

Contribution of simulation to engine design

The thermofluids and simulations team have used Simcenter tools in the engine design process since 1999. Simcenter is a part of Xcelerator, a  comprehensive and integrated portfolio of software and services from Siemens Digital Industries Software and is used for computational fluid dynamics (CFD) and internal combustion engine (ICE) analyses. Building the Wärtsilä 31 engine was the first time CFD was used so early in the design process. Liavåg and his team ran initial simulations on potential geometries even before the engine’s design was completed in the 3D computer-aided design (CAD) software.

comprehensive and integrated portfolio of software and services from Siemens Digital Industries Software and is used for computational fluid dynamics (CFD) and internal combustion engine (ICE) analyses. Building the Wärtsilä 31 engine was the first time CFD was used so early in the design process. Liavåg and his team ran initial simulations on potential geometries even before the engine’s design was completed in the 3D computer-aided design (CAD) software.

– We looked at potential new system features for combustion on existing engine geometries, says Liavåg. This gave us the freedom to try new things, as we could make mistakes virtually rather than creating expensive prototypes.

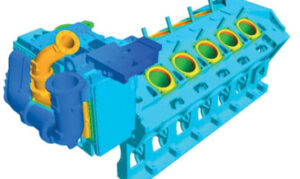

As the engine design evolved, CFD was used to analyze additional parts of the engine, including the complete charge air and exhaust manifold systems.

– You can go around the whole engine and point out, ‘Here we have simulated, here we have simulated, here we have simulated,’ says Liavåg. – CFD helped make many small modifications, and these add up to a significant impact on the final engine design.

Liavåg says he was surprised at how much they could simulate using Simcenter STAR-CCM+: – I thought it was a joke when one of the guys proposed to model the complete charge air manifold system with transient fluctuations and all, he says. Believe me, that is one big system.

Thermal data from the complete charge air system was mapped onto solid models for stress analysis. In addition, the air cooler intake ducts were redesigned, improving flow uniformity. The wide variety of physical models available in Simcenter STAR-CCM+ meant that many different engine components could be analyzed. For example, the team simulated oil splashing within moving engine pistons, using the volume of fluid (VOF) model for the piston motion’s oil and overset meshes.

Conjugate heat transfer (CHT) simulations provided thermal data which could be mapped onto solid models for stress analysis, and loose fluid/solid coupling was also used directly in Simcenter STAR-CCM+ to model the complete exhaust manifold. This approach enabled thermal analysis of different components such as bellows and fastening clamps.

Conjugate heat transfer (CHT) simulations provided thermal data which could be mapped onto solid models for stress analysis, and loose fluid/solid coupling was also used directly in Simcenter STAR-CCM+ to model the complete exhaust manifold. This approach enabled thermal analysis of different components such as bellows and fastening clamps.

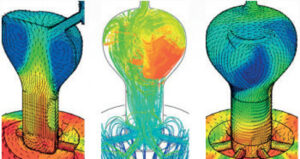

The thermofluids and simulation team also used CFD simulations for the in-cylinder combustion analysis to ensure a safe, fuel efficient engine.

– Thanks to the strong support and collaboration with experts at Siemens, we can run a full engine cycle in one day with our power licensing, says Liavåg. – For the development of the Wärtsilä 31 engine, the team performed over 660 gas combustion simulations and way more than 1,200 diesel combustion simulations. These helped us optimize the engine’s piston geometries, fuel injector specifications and operating parameters.

This was the first time a Wärtsilä engine was developed in diesel, gas, and dual-fuel versions from the outset, and these advanced CFD analyses helped ensure the design was optimized for both diesel and gas fuel operation. Inlet and exhaust ports were also optimized using CFD, as were many critical components such as the prechambers of the gas engine version.

Cross-company collaboration

While the thermofluids and simulation team are the main users of CFD simulation, it’s use is becoming more widespread throughout the company. Engine design engineers are now using embedded CFD within Siemens’ NX software, their CAD tool, to analyze flow through engine components from the very first design.

– Involving basic CFD as part of the CAD process means we receive fewer bad designs which we have to reject; it reduces the virtual scrap rate, says Liavåg.

The thermofluids and simulation team also works closely with the structural analysis team to create a thermal management analysis process based on CHT simulations and in-cylinder CFD. As part of this project, finite element (FE) engineers use Simcenter STAR-CCM+ to build some conjugate heat transfer models.

With this increased use of simulation software, efficient use of computing resources is a priority. Wärtsilä has one of the biggest computer clusters in Finland; this capacity is used for both FE and CFD analysis. The power licensing option of Simcenter STAR-CCM+ means the teams are not limited in their use of parallel cores, allowing them to meet their varying simulation needs.

– The power licensing option was a quantum leap forward in capability for us, as it allowed us to ride the wave of hardware capacity improvement,”says Liavåg. We can use our computing resources to their maximum capacity and run full engine cycle simulations in just one day.

Final design testing

Wärtsilä’s use of CFD early in the design process not only improved the design but also reduced the amount of engine rig testing required. A big bore engine can burn several tons of heavy fuel per hour. Reducing the physical testing saves both time and energy and reduces costs.

– Our use of CFD meant we had a better understanding of what to expect before we started the engine in the lab, and this allowed us to use our testing capacity in a much smarter way, says Liavåg.

This way of working, using simulation through ideation, concept and detailed design stages, meant that the final engine exceeded the planned performance targets from the very first version. Instead of a prototype stage lasting several years, with subsequent release stages to fix later problems, the Wärtsilä 31 has already been optimized and rigorously tested via virtual validation.

Reflecting on the changes in the development process over the years, Liavåg says that, “It is the way of working that is the real revolution. We are using the tools available to us to create the best possible product in a way that was not possible 20 years ago. We would not have been able to work this way without the modern CAE tools and HPC systems.

Powering the ships of the future

All of these different contributions from CFD to the design process can be seen in the final engine’s efficiency, contributing to the reduction in CO2 emissions compared to equivalent engines. Diesel fuel consumption can run as low as 165 g/kWh, while the total hydrocarbon emissions of the gas engine have been reduced by up to 50 percent. The engine has been optimized to comply with all existing and anticipated emission regulations and has an expected lifetime of 40 years.

CFD simulation is now embedded in Wärtsilä’s design process and has been instrumental in helping the company bring this new engine to market. The Wärtsilä 31 engine was officially unveiled at the Nor-Shipping 2015 maritime trade fair held in Oslo, Norway, and Wärtsilä has already fulfilled orders for both gas and diesel models.

As shipowners look to meet efficiency regulations, Wärtsilä is meeting that market demand, aided by its use of Simcenter STAR-CCM+ and digital design.