Customized special-purpose trucks produced with Siemens PLM Software

The Hungarian truck manufacturer GIF Modul Kft. (GIF) develops and builds trucks with special superstructures for the automotive industry. The company also enjoys a reputation as a leading manufacturer of heavy-duty cranes. Among the greatest challenges faced by GIF Modul are designing complex moving components and finding solutions to individual customer requirements. This prompted GIF Modul to implement Solid Edge from Siemens PLM Software. This solution enables the company to shorten the design phase and at the same time improve its competitive standing and product engineering process.

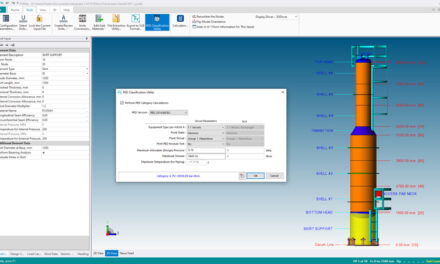

The engineering and construction of special vehicles with lifting equipment such as heavy-duty cranes is a complex matter. The reliability and usability of the finished truck can only be guaranteed if the specifications for the vehicle, the superstructure and the lifting equipment are precisely in synch, creating a single cohesive unit. This is why GIF develops and builds all the components in-house. To ensure a lean, highspeed engineering process and enable the implementation of specific customer requirements, GIF initially opted to implement the Solid Edge 2D Drafting Software from Siemens PLM Software. As the company started work on a new project to design a winch involving a large number of moving parts, GIF Modul decided to upgrade its Solid Edge software package to include the 3D function. This brought about a tangible reduction of the design workload.

The engineering and construction of special vehicles with lifting equipment such as heavy-duty cranes is a complex matter. The reliability and usability of the finished truck can only be guaranteed if the specifications for the vehicle, the superstructure and the lifting equipment are precisely in synch, creating a single cohesive unit. This is why GIF develops and builds all the components in-house. To ensure a lean, highspeed engineering process and enable the implementation of specific customer requirements, GIF initially opted to implement the Solid Edge 2D Drafting Software from Siemens PLM Software. As the company started work on a new project to design a winch involving a large number of moving parts, GIF Modul decided to upgrade its Solid Edge software package to include the 3D function. This brought about a tangible reduction of the design workload.

Wide-ranging integrated functions

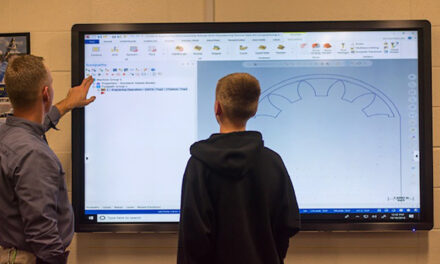

Once designed, parts can be used multiple times – which speeds up the entire process. It was important for GIF Modul to be able to quickly localize existing parts. Solid Edge makes short work of this with its integrated product management capabilities, which allow engineers to quickly search for components designed in Solid Edge using either the file name or pre-defined properties. To design the truck subframes and platforms, the GIF engineers use the sheet metal and welding design capabilities of Solid Edge, which allows them to effortlessly create sheet metal models on the basis of 2D drawings. The use of Synchronous Technology supports independent editing of various functions.

Once designed, parts can be used multiple times – which speeds up the entire process. It was important for GIF Modul to be able to quickly localize existing parts. Solid Edge makes short work of this with its integrated product management capabilities, which allow engineers to quickly search for components designed in Solid Edge using either the file name or pre-defined properties. To design the truck subframes and platforms, the GIF engineers use the sheet metal and welding design capabilities of Solid Edge, which allows them to effortlessly create sheet metal models on the basis of 2D drawings. The use of Synchronous Technology supports independent editing of various functions.

Fast, simple implementation

– My concern was to implement the software quickly enough that we didn’t lose too much valuable time, recalls Zoltan Imre, CEO (Chief Executive Officer) at GIF.

– We actually managed to design our new project with Solid Edge, and to manufacture the parts on time. As well as speeding up its engineering time, Solid Edge has also allowed GIF Modul to cut delivery periods, resulting in increased customer satisfaction and a clear competitive advantage.