“MF Gloppefjord” running between Anda and Lote from January 2018 with Siemens propulsion technology

To comply with the country’s stringent environmental regulations governing ferry emissions, the Norwegian ferry operator Fjord 1 has opted to expand its fleet using all-electric propulsion solutions. The two latest additions to the fleet use zero emission technology. The complete propulsion and automation solution used comes from Siemens. This sustainable solution has allowed the operator to successfully run Norway’s first totally zero-emission ferry route. These environmentally friendly ferries are also highly cost-efficient to run.

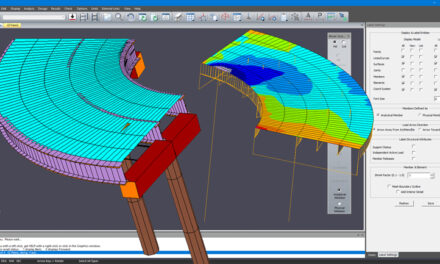

The “Ampere” equipped with propulsion and automation technology from Siemens was the first all-electric ferry of its kind. It has now been joined by two more: the “MF Gloppefjord” and the “MF Eidsfjord”. Die “MF Gloppefjord” entered service in January 2018 traversing the 2.4-kilometer route E39 between the landing stage in Anda and the small waterside town of Lote on Norway’s west coast, and the “MS Eidsfjord” is due to follow suit in the near future. Each of the two ferries has a capacity for up to 120 cars plus twelve trailers and is able to transport up to 349 passengers per trip. This route is the first for which the Norwegian highway authorities have stipulated the mandatory use of zero-emission technology. To comply with this legislation, the “MF Gloppefjord” has been equipped with BlueDrive PlusC propulsion technology from Siemens.

Optimum use of resources

The minimum requirement was for the deployment of one ferry operating with zero emissions, and another using a low-emissions propulsion system. Arild Austrheim, Maritime Technical Director at Fjord1, explains the rationale for choosing battery-only propulsion for both:

The minimum requirement was for the deployment of one ferry operating with zero emissions, and another using a low-emissions propulsion system. Arild Austrheim, Maritime Technical Director at Fjord1, explains the rationale for choosing battery-only propulsion for both:

– Given that the necessary infrastructure is available on land, our aim was to maximize the benefit from this investment by using two zero-emission ferries. The BlueDrive PlusC solution from Siemens encompasses lithium-ion batteries as an energy storage system, remote control of the propellers, energy management as well as an alarm and monitoring system and a remote diagnostic system. After every crossing, the storage batteries are charged using a connection to an on-shore charging station. The automation system used on board the ferries is connected to the automation and control system of the on-shore charging station over a W-LAN (Wireless Local Area Network) link This ensures that the optimum possible charging process is achieved with the aid of a complete bridge-togrid solution from Siemens.

Reliable, cost-efficient and sustainable solution

The BlueDrive PlusC solution was developed in Norway based on technology originally designed for offshore shipping. This wealth of experience has provided a mature, fully developed system which can be relied on in even the toughest conditions. The BlueDrive PlusC solution provides ship owners with the assurance of the best environmental credentials, alongside improved safety and economy.