Compared to the traditional manufacturing industry, the woodworking industry is much more well known for the charm and aesthetics of its parts. Woodworking customers expect a certain standard of beauty on top of a product’s function. Meeting both expectations—aesthetics and utility—often poses a problem for woodworking shops, and it can even cut into revenue. When the economy stumbles and material prices soar, like during the pandemic, a woodworking company’s approach to this dilemma can mean either its demise or success. Luckily, many shops are starting to appreciate the value of CNC (computer numerical control). CNC woodworking can add an element of precision and efficiency that offers just that profitability, especially when paired with CAD/CAM software.

What are common applications for CNC woodworking?

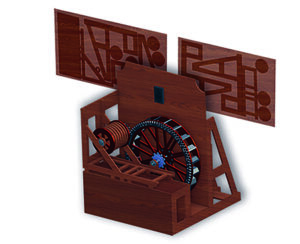

Any production shop can benefit from the incorporation of CNC, regardless of what its specialty might be. For attractive, eye-catching signs, operators can rely on CNC  routers to carve out text and images. For intricate banisters, operators can turn to CNC lathes. For the complex and incredibly precise inner components of a clock, operators can use CNC mills. Its applications are only limited by the creativity of its users, and the production of almost any piece can be improved with CNC woodworking. Regardless of the CNC’s application, productivity is essential to growing any business.

routers to carve out text and images. For intricate banisters, operators can turn to CNC lathes. For the complex and incredibly precise inner components of a clock, operators can use CNC mills. Its applications are only limited by the creativity of its users, and the production of almost any piece can be improved with CNC woodworking. Regardless of the CNC’s application, productivity is essential to growing any business.

What are the benefits of woodworking CAD/CAM software?

In woodworking, like any industry, success depends on precision, reliability, and speed of product delivery. Using a CAD/CAM software solution helps to meet these rigorous demands by simplifying the programming process and allowing craftsmen to focus solely on creating the most beautiful and functional parts possible. CAD offers easy visual design tools for creating beautiful parts, and CAM automatically generates the code that will run the machine. The CAD portion of the solution should allow quick, intuitive design of even the most intricate and ornate 3D parts. The CAM should provide flawless G-code to the CNC machine so that parts are machined quickly and without error. Without the software solution, programmers would be resigned to having to manually draw out the products and manually learn and create the confusing G-code to run their machine. In addition, CAD/CAM software offers one more powerful benefit— repeatability. Once a design is created and the machining is programmed, that effort can be banked for future use. Projects can be re-run to the same level of precision, and changes can be made to the original project without having to start from scratch.

Mastercam CAD/CAM software for woodworking

Mastercam offers the widest range of CAD/CAM tools for solving woodworking machining challenges. Our array of machining solutions for woodworking helps maximize productivity without sacrificing quality. Whether for rough or finish machining, Mastercam provides the tools needed to streamline and automate your woodworking tasks, including:

Mastercam offers the widest range of CAD/CAM tools for solving woodworking machining challenges. Our array of machining solutions for woodworking helps maximize productivity without sacrificing quality. Whether for rough or finish machining, Mastercam provides the tools needed to streamline and automate your woodworking tasks, including:

• Widest range of CAM tools for solving machining challenges.

• Built-in nesting, engraving, aggregate tools, and much more.

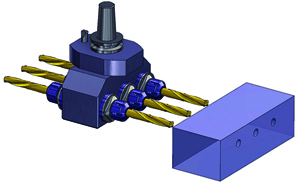

• Streamlined multiaxis cutting, trimming, and drilling.

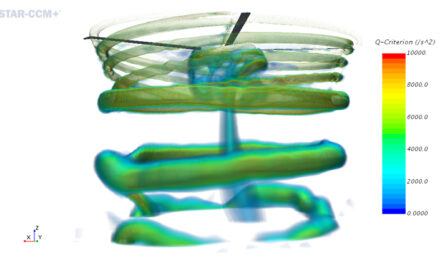

• Dynamic Motio boosts tool life and decreases cutting time.

• Program free-flowing surfaces and geometry in minutes.

• Save machining strategies to a library for use on similar parts.

• Optimized output with nesting for reduced waste and greater material use.

• Simplified detail and relief work with Mastercam Art.

• Translate 2D artwork to 3D machinable pieces quickly and easily. Its CAM side not only saves machining strategies to a library for use on similar parts, but also offers streamlined cutting, trimming, and drilling for Router, Lathe, Mill, and Multiaxis. Our solutions are designed to complement the specific needs of any shop, from design to router to turning, multitasking, and more. Check out the full array of Mastercam products to find the right solutions for your manufacturing challenges.

Mer info: www.ameab.se