Systems engineering and leadership skills empower the next generation of engineering talent. The University of Michigan is a preeminent public research university in Michigan. The College of Engineering ranks fourth among engineering programs in the U.S. The Department of Aerospace Engineering, founded in 1914 and the oldest undergraduate program in the U.S., is consistently highly ranked in the top three nationwide. Seven astronauts are among the more than 4,000 alumni.

Partnership with Siemens Digital Industries Software

Siemens has granted software for several different schools within engineering. All students at the College of Engineering have access to Siemens software. In the past few years, Siemens has grown its commitment to supporting innovation on campus by upgrading a technical and collaboration space in the Wilson Student Team ProjectCenter for use by all students for design reviews and other purposes. Siemens Digital Industries Software has also demonstrated their commitment to the future of education by co-creating massive open online course content.

Teaching systems engineering and leadership to aerospace students

In early 2020, George Halow, professor of practice in the university’s Department of Aerospace Engineering, reached out to Siemens to discuss his ideas for integrating systems engineering and business leadership instruction into the aerospace curriculum. Halow joined the university in 2019 after a 31-year career at Ford. He wanted to help develop skill sets and knowledge that would fill the gap between industry needs and new employee capabilities.

In early 2020, George Halow, professor of practice in the university’s Department of Aerospace Engineering, reached out to Siemens to discuss his ideas for integrating systems engineering and business leadership instruction into the aerospace curriculum. Halow joined the university in 2019 after a 31-year career at Ford. He wanted to help develop skill sets and knowledge that would fill the gap between industry needs and new employee capabilities.

As advances in technology are transforming industry at a record pace, there is a need for highly skilled technical specialists who can innovate beyond the traditional boundaries between engineering disciplines. The next generation of smart products are complex systems of systems that require a model-based systems engineering (MBSE) approach. Unfortunately, formal instruction is often lacking at the undergraduate level.

In 2020 Michigan Aerospace Engineering introduced a new systems engineering and leadership course. The laboratory exercises for the course use system development lifecycle (SDLC) principles to provide instruction in key systems engineering tools and processes, as well as leadership and business skills.

Focus on student project teams

– We wanted to focus on student project teams because they actually bring a disciplined project that has competition rules and regulations, Halow says. – Engineering students gain critical hands-on design experience as well as important team, organizational and management skills.

The projects have all the subsystems that will be affected. They are ready-made projects to which we could apply these learnings.– Student competition projects are a microcosm of the product development cycle in industry. They begin with establishing new requirements, then cascade those requirements down to systems and subsystems, Halow explains. Students design, build and test to the requirements, then verify and validate the design, and the result is what the teams compete with.

The projects have all the subsystems that will be affected. They are ready-made projects to which we could apply these learnings.– Student competition projects are a microcosm of the product development cycle in industry. They begin with establishing new requirements, then cascade those requirements down to systems and subsystems, Halow explains. Students design, build and test to the requirements, then verify and validate the design, and the result is what the teams compete with.

Close collaboration with Siemens experts

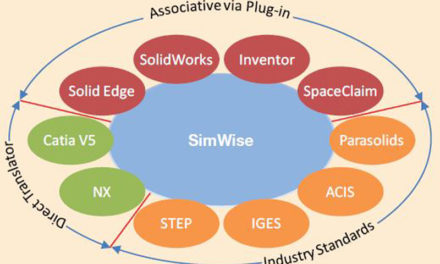

To introduce the design-build-test-fly cycle, the university enlisted the help of Siemens experts to develop a series of five labs that students work through in the first weeks of the class. Through virtual meetings, the Siemens experts collaborated with university personnel to thoroughly understand the requirements and learning objectives of the course and discussed the tools and technologies that could be applied to achieve the objectives. The labs employ leading-edge design, engineering, manufacturing and product lifecycle management solutions from the Xcelerator™ portfolio of solutions and services from Siemens Digital Industries Software.

Systems engineering

Tony Komar, a Siemens systems engineering evangelist, worked with professors, students and instructional assistants, helping them understand the value of the systems engineering methodology.

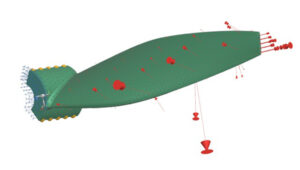

– I built out a systems model of a drone with embedded requirements. Students are given the model for a requirements decomposition and cascade exercise. At the system level you may have requirement for a vertical acceleration, but at the logical level the requirement may be the speed of the motor  rotation needed to deliver thrust from a propeller.

rotation needed to deliver thrust from a propeller.

The lab exercise uses Teamcenter software and Capella, an open-source system modeling tool. The model included requirements for operating conditions, scale, lift/thrust and power, cost and load limits.

Computer-aided design

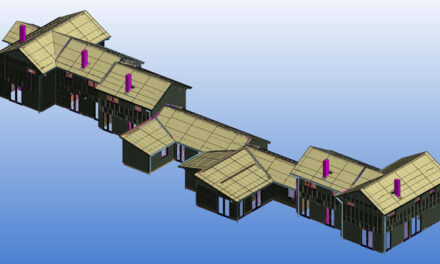

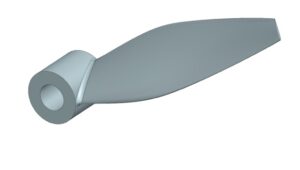

The second lab exercise involved computer-aided design (CAD) technology, for which the project teams used NX software to design e.g. a 3D fin and propeller blades. Using solid modeling techniques, students create 3D models of assemblies to evaluate design parameters..

System simulation

In the following lab, project teams used the assembly developed in the CAD lab exercise and employed Simcenter Amesim software for multi-domain system simulation to add a power source, a servo, a motor control board, a joystick controller and an Arduino.

Simulation and optimization

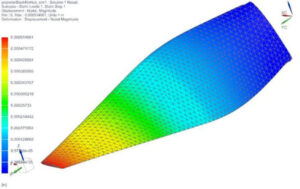

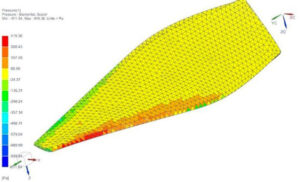

The subsequent lab focused on simulation and optimization, for which the teams used Simcenter STAR-CCM+ software for computational fluid  dynamics (CFD) and Simcenter Nastran software to calculate the thrust/lift of the propeller at different speeds.

dynamics (CFD) and Simcenter Nastran software to calculate the thrust/lift of the propeller at different speeds.

Manufacturing collaboration

The final lab exercise was designed to introduce the project teams to key manufacturing considerations. With investment, cost and volume information provided in the lab, the students were asked to make key tradeoff decisions involving costs, materials, tooling, labor and manufacturing and assembly time.

Closing the skills gap

With a groundbreaking engineering course based on real-world MBSE product development tools and techniques, the University of Michigan is  empowering students with knowledge and hands-on skills. .

empowering students with knowledge and hands-on skills. .

– We want to take this approach into other dimensions, says Halow. If it works in aerospace, why can’t it work in mechanical or biomedical or in any other engineering discipline?.