Automotive interiors manufacturer uses Teamcenter to realize cost savings in component and tool procurement

Siemens Digital Industries Software’s product cost management solution enables Grammer to reduce calculation processing times

Innovations for more growth

The Grammer AG (Grammer) success story began over 100 years ago when it was established as a saddlery. Since that time, the company has transformed itself from a regional supplier of seat cushions to a global player in the automotive and commercial  vehicle industry. Today, Grammer specializes in developing and producing components and systems for automobile interiors as well as driver and passenger seats for commercial vehicles. The Grammer Automotive Division provides headrests, armrests and center consoles to well-known premium car manufacturers as well as system suppliers. The seating systems division comprises truck, off-road, train and bus seating.

vehicle industry. Today, Grammer specializes in developing and producing components and systems for automobile interiors as well as driver and passenger seats for commercial vehicles. The Grammer Automotive Division provides headrests, armrests and center consoles to well-known premium car manufacturers as well as system suppliers. The seating systems division comprises truck, off-road, train and bus seating.

Check purchase prices accurately and continuously

The procurement department of Grammer must continuously consider whether it is paying an appropriate price for parts and tools. It is important to create cost transparency for purchasing parts, tools, their functions, manufacturing processes and logistics processes.

– Our procurement department is constantly having to optimize purchased parts and tool expenses and to ensure improved performance by the suppliers, says Manfred Baumer, tool management, Grammer Interiors Europe Division.

Grammer identified weaknesses in the purchasing process and decided to standardize the costing software. One of the decisive requirements for the new system was connecting product costs and tool costs in a single software. This was done in order to simulate the effects of changes in tool cost calculation on product costs. Grammer decided to introduce Teamcenter software Product Cost Management, the integrated cost calculation solution for products and tools from Siemens Digital Industries Software.

Knowledge-based purchase price analysis

With Teamcenter Product Costing, cost analysts structure the use of materials and model the necessary manufacturing and overhead processes for the production of the purchased parts and evaluate them with costs. Therefore, components are broken down into their individual parts and documented in the same way as the structure of a bill-of-materials (BOM). Each individual part is evaluated based on cost analysis, which means the value-added chain is broken down into manufacturing plans. This includes materials, technologies and manufacturing processes with the associated tool costs, processes and setup times; the required personnel, location-related energy and labor costs and the overhead costs for the indirect areas involved.

Current benchmark data that is available in Teamcenter such as machine data and costs for labor, overhead, location and manufacturing technologies can be used in Teamcenter Product costing to determine optimal pricing. Based on the individual prices of the components and their BOM and work plans, a product cost structure is set up.

This analysis makes the total price transparent. Consequently, Grammer can determine the most they are willing to pay for a component. The result is a detailed and transparent cost breakdown. The calculation results are compared with the price offered by the supplier.

Tool purchasing at appropriate prices

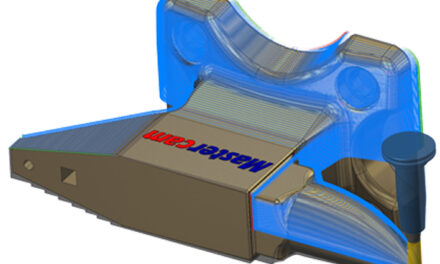

With Teamcenter Tool Costing, Grammer’s cost analysts can carry out shadow calculations to check the calculations of the suppliers. Teamcenter can be used to provide information such as tool technology data and 3D data from NX software to create cost calculations using the parametric method. A number of standard display functions in the 3D tool such as measurements and sections enable undercuts, ribs, etc., to be easily and flexibly recognized, which are then provided with cost information in Teamcenter Tool Costing. The knowledge database integrated in Teamcenter, which contains reference data and integrated cycle time calculators, ensures a company-wide uniform standard of calculation.

As a rule, Grammer Procurement expects to receive much more than just a tool price from a supplier. This means that offers from suppliers usually have to be submitted as cost breakdowns. With Teamcenter Tool Costing, cost breakdown templates can easily be imported by the procurement department and then immediately compared with their shadow calculation.

As a rule, Grammer Procurement expects to receive much more than just a tool price from a supplier. This means that offers from suppliers usually have to be submitted as cost breakdowns. With Teamcenter Tool Costing, cost breakdown templates can easily be imported by the procurement department and then immediately compared with their shadow calculation.

Differences in the calculations are immediately transparent and facilitate a fact-based discussion between procurement and the supplier. Using Teamcenter Tool Costing, the procurement department at Grammer has transparency into price composition and relevant cost drivers and can evaluate available offers in detail in the context of cost and technology.

A win-win situation

With the collected knowledge, supplier workshops are carried out to uncover potential for improvement. Knowing the exact cost structure of the suppliers enables the procurement department to argue and negotiate based on facts.

– With the purchase price analysis in Teamcenter Product Cost Management, Grammer procurement finds immediate and sustainable savings potential and benefits due to a strengthened supplier relationship that takes place on an even-handed basis, says Baumer.

The potential savings can be implemented by the suppliers not only for Grammer, but also for all other customers. This also gives them a market advantage.

Create market advantages in the future too

With Teamcenter Product Cost Management, the procurement department knows in advance exactly at what price the supplier will offer.

– We were able to use Teamcenter Product Cost Management to reduce the calculation time to determine the purchase price, says Baumer. To this end, Grammer will continue to use the interaction between Teamcenter Tool Costing and Teamcenter Product Costing to create a fully integrated calculation solution.