Several years ago, Materialise outlined an ambitious roadmap to evolve its entire software suite to a model that offers customers cloud-based access to a complete platform of software tools. This platform strategy is based on an important trend in the manufacturing industry: the increasing use of 3D printing, not just for prototyping operations isolated from the conventional manufacturing process, but for repeat production of small and mid-sized series and mass customization. In other words, an irreversible move to integrate 3D printing as one of the processes in the overall production of goods.

Our new CO-AM platform was developed to address this shift in production by giving companies cloud-based access to a full range of software tools that allow them to plan, manage, and optimize their 3D printing operations as part of a connected manufacturing process.

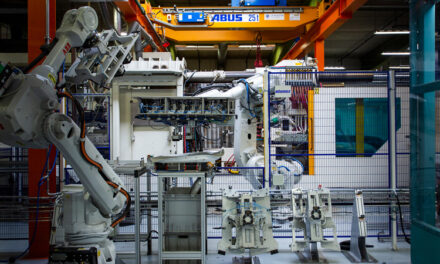

More recently, we have seen another important trend. Systemic shocks, including the Corona crisis, global supply chain issues, geo-political tensions, and growing sustainability concerns, have revealed vulnerabilities to the traditional, centralized production model. Smart, digital production technologies, like 3D printing, enable a shift towards multiple smaller-scale manufacturing sites closer to customers. A clear sign that the factory of the future will not be a single, central location.

This new digital, distributed production environment revolves around one key asset – data. As data takes on a greater role and is shared among industrial companies, suppliers, and contractors, the importance of data security grows as well.

In today’s digital age, data security is important in any form of manufacturing. Traditional manufacturers use data to integrate various steps of a process, store and share information regarding efficiencies and best practices, or control automated functions on the production line. Similarly, smart manufacturing, like 3D printing, requires companies to share their unique designs and digital assets among industrial companies and suppliers. That’s why smart manufacturing at multiple digital production sites distributed around the world will only truly take off when companies are sure that their design data remains secure.

But with 3D printing, there’s more to it. With 3D printing, the material and the product are created at the same time.

Arguably, this makes 3D printing more complex than its conventional counterpart. Manufacturers that plan to scale up the production of a 3D-printed part into the thousands or millions need to optimize and fine-tune their unique print process in order to make it efficient, reliable, and repeatable across multiple production sites. Creating smart production processes to make sure all components have the same quality, irrespective of where they are produced, is complex and time-consuming, but it allows companies to leap ahead of the competition. That’s why, in addition to data security, data integrity has also become top of mind for companies that embrace digital manufacturing.

To address this increasing need for data security and data integrity in distributed additive manufacturing, I’m thrilled to share the news that Materialise has acquired Identify3D, a company that develops software to encrypt, distribute, and trace the flow of digital parts across complex supply chains. Through this acquisition, we will add a new layer of security within our CO-AM platform, making it the most secure software platform for 3D printing on the market. By enabling companies to protect their designs at every step of the process and allowing engineers to couple designs with specific production criteria, we are creating new opportunities to scale up 3D printing operations as part of a digital and distributed production environment.

With new capabilities to lock parameters in place for the materials and printers used as well as the production of the part itself, CO-AM will now give companies the confidence they need to share the data required for effective, quality manufacturing. By preventing counterfeits and ensuring that maliciously or inadvertently modified, substandard, or uncertified parts cannot enter the physical supply chain, we are removing yet another roadblock in unlocking the potential of 3D printing for distributed, volume production.