Networked design and manufacturing with Siemens PLM Software secures market lead

Shenzhen, China. ASM Pacific Technology Ltd. (ASM) produces semi-conductors and equipment used in the manufacture of LEDs (light-emitting diodes) for chip producers the world over. To create a closer link between computer-based design and production, and to reduce engineering times, ASM has opted to use solutions from Siemens PLM Software. This decision has enabled ASM to improve its manufacturing efficiency and product quality by up 70 percent.

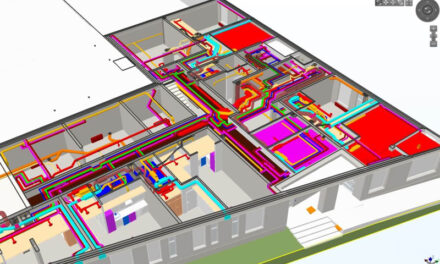

![]() Like a great many other companies, world market leader ASM faces the challenge of engineering and manufacturing increasingly complex products within ever shorter manufacturing cycle times. To be sure of maintaining its position at the leading edge of the industry, ASM earkmarks ten percent of its profit every year for investment in product development. However, development was compromised in terms of speed and quality by the geographical separation of its design, development and production facilities. One difficulty encountered was the impossibility of transferring 3D product models directly into the manufacturing process due to incomplete product information. The exchange of data between computeraided design (CAD) and manufacturing (CAM) was also timeconsuming and difficult. The key to achieving an optimum production process was to implement digitalization using the NX software from the Siemens PLM Software solution portfolio.

Like a great many other companies, world market leader ASM faces the challenge of engineering and manufacturing increasingly complex products within ever shorter manufacturing cycle times. To be sure of maintaining its position at the leading edge of the industry, ASM earkmarks ten percent of its profit every year for investment in product development. However, development was compromised in terms of speed and quality by the geographical separation of its design, development and production facilities. One difficulty encountered was the impossibility of transferring 3D product models directly into the manufacturing process due to incomplete product information. The exchange of data between computeraided design (CAD) and manufacturing (CAM) was also timeconsuming and difficult. The key to achieving an optimum production process was to implement digitalization using the NX software from the Siemens PLM Software solution portfolio.

Seamless link between CAD and CAM

– We began using NX CAM software from Siemens PLM Software in manufacturing factories in 2000, recalls Chen Lizhi, Head of MIS Information and Telecommunications Technology at ASM.

– We have deployed more than 100 suites in factories all over the world. The digital transformation using the Siemens solution has been a resounding success, enabling ASM to raise its productivity to a whole new level. The most clearly evident effect was the trouble free link created between design and manufacturing. ASM achieves this by using the NX feature FBM (feature-based machining) which allows NX CAM (computeraided manufacturing) to automatically read product and manufacturing information (PMI), tolerances, information about surface machining and a whole host of other data stored in the 3D model. The system is also able to use this information as the basis for automatic calculation of the optimum machining method. The simulation and verification function integrated in NX CAM also reduces potential sources of error, as the ASM engineers no longer need to carry out physical tests.

70 percent quality and efficiency improvement

– NX CAM’s feature-based machining enables us to truly experience the seamless connection between CAD and CAM, enabling manufacturing to respond more quickly to design changes, thus significantly reducing the time of responding to user requirements and reducing time-tomarket, says Hu Dewen, senior CAD/CAM manufacturing manager at ASM.

– Our statistical results show that feature-based machining and PMI have improved the production efficiency and quality of ASM by 70 percent, thus saving a lot of valuable time.