Race bike design with Siemens software combines aerodynamics and rider comfort

Waterloo/Wisconsin, USA. The Trek Bicycle Corporation (Trek) is one of the largest bicycle manufacturers in the world. Trek uses modern technology such as Siemens PLM Software solutions when designing and developing its bikes not only to satisfy aerodynamic demands but also to ensure the bike provides the rider with a positive response. Elements of aerodynamics and comfort are brought together under one umbrella which provides Trek with automatic optimization of the frame design as well as optimum positioning of, for example, the rider and water bottles. By using the Siemens solutions, Trek was able to develop a race bike which was equally aerodynamic and comfortable and to save a significant amount of time in product design and therefore cost as well.

Waterloo/Wisconsin, USA. The Trek Bicycle Corporation (Trek) is one of the largest bicycle manufacturers in the world. Trek uses modern technology such as Siemens PLM Software solutions when designing and developing its bikes not only to satisfy aerodynamic demands but also to ensure the bike provides the rider with a positive response. Elements of aerodynamics and comfort are brought together under one umbrella which provides Trek with automatic optimization of the frame design as well as optimum positioning of, for example, the rider and water bottles. By using the Siemens solutions, Trek was able to develop a race bike which was equally aerodynamic and comfortable and to save a significant amount of time in product design and therefore cost as well.

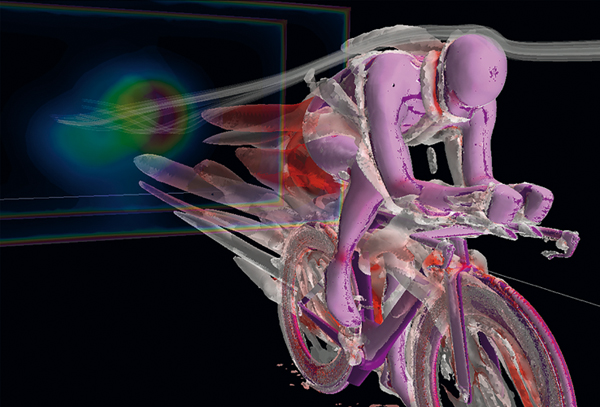

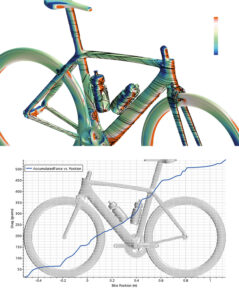

Bicycle design is based in part on complex physics. The compromise between aerodynamic optimization of efficiency and the ride quality is a key challenge for Trek – and this was the case when developing the new Madone race bike. To achieve this, Trek used a combination of computational fluid dynamics (CFD) and finite element analysis (FEA). The solution consisted of a tube-in-tube design which separated aerodynamics and comfort. The other missing item was a tool for optimizing the frame design. For Trek, it was important that this tool could be incorporated into the existing applications architecture which included the Simcenter Star-CCM+ Computer Aided Engineering (CAE) software and the SolidWorks Computer Aided Design (CAD) solution. The Siemens PLM Software and the Heeds software which forms the interface between various different engineering tools and automatically optimizes a design was the ideal solution for the engineers.

Bicycle design is based in part on complex physics. The compromise between aerodynamic optimization of efficiency and the ride quality is a key challenge for Trek – and this was the case when developing the new Madone race bike. To achieve this, Trek used a combination of computational fluid dynamics (CFD) and finite element analysis (FEA). The solution consisted of a tube-in-tube design which separated aerodynamics and comfort. The other missing item was a tool for optimizing the frame design. For Trek, it was important that this tool could be incorporated into the existing applications architecture which included the Simcenter Star-CCM+ Computer Aided Engineering (CAE) software and the SolidWorks Computer Aided Design (CAD) solution. The Siemens PLM Software and the Heeds software which forms the interface between various different engineering tools and automatically optimizes a design was the ideal solution for the engineers.

Optimum water bottle position

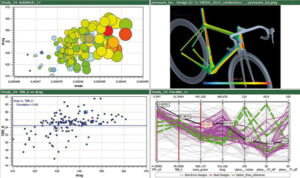

Heeds assesses and automates the engineer’s current design workflow. The data is based on the design and analysis tools chosen by the user. On the Madone race bike, this software was used to define the optimum, aerodynamic position of the water bottle to ensure the Madone is the fastest race bike under real conditions. In the first CAD model, the water bottles were positioned at random locations on the down tube and the seat tube. Heeds varied the bottle positions and adapted the iteration values to the previous resistance reactions on a step-by-step basis. After 140 iterations, the end result produced a 5.5 percent reduction in the overall resistance when the bottle is located as low as possible and aligned with the bottom bracket.

Heeds assesses and automates the engineer’s current design workflow. The data is based on the design and analysis tools chosen by the user. On the Madone race bike, this software was used to define the optimum, aerodynamic position of the water bottle to ensure the Madone is the fastest race bike under real conditions. In the first CAD model, the water bottles were positioned at random locations on the down tube and the seat tube. Heeds varied the bottle positions and adapted the iteration values to the previous resistance reactions on a step-by-step basis. After 140 iterations, the end result produced a 5.5 percent reduction in the overall resistance when the bottle is located as low as possible and aligned with the bottom bracket.

Practical, comfortable, and efficient

The most important benefit of Heeds, Trek’s engineers say, is what they call an ensemble-based analysis which allows previously unknown correlations between design variables and performance attributes to be uncovered. Before this software was introduced, engineers would typically have to analyze 30 to 50 design iterations while Heeds can complete 500 to 1,000 iterations in the same amount of time. By using Siemens solutions, Trek has been able to develop an aerodynamic race bike with maximum rider comfort and save a significant amount of time in the product design process and therefore cost as well.