Automotive supplier digitalizes manufacturing process with Siemens software

Vinh Yen/Vinh Phuc, Vietnam. Cosmos Industrial Co. Ltd. (Cosmos) is one of the leading parts manufacturers for the Vietnamese automotive industry. The company relies on highly innovative development and high product quality to remain competitive in the international market. As well as using modern machines and machining centers, Cosmos also benefits from the advantages of digitalizing its production process, using solutions from the Siemens PLM Software portfolio. This means the supplier is able not only to meet its customers’ many diverse requirements but it was also able to increase productivity by 50 percent and significantly reduce manufacturing times and costs at the same time.

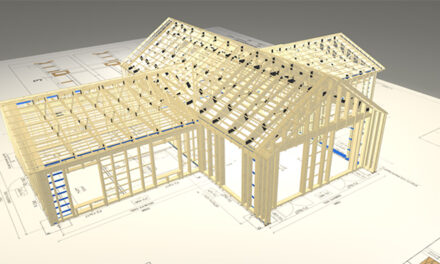

In recent years, Cosmos has invested heavily in machines, equipment and software solutions including 3-axis and 4-axis machining centers. These machining centers can be programmed using the NX software from the Siemens PLM Software portfolio. The reason for introducing NX was the partnership between Cosmos and Vietbay, a Siemens solutions partner. This allowed the company to digitalize the whole part manufacturing process, starting with the CAD model, and right through to the finished part. The previous solution did not offer Cosmos any options for manufacturing particularly complex components which led to a decline in customer orders.

In recent years, Cosmos has invested heavily in machines, equipment and software solutions including 3-axis and 4-axis machining centers. These machining centers can be programmed using the NX software from the Siemens PLM Software portfolio. The reason for introducing NX was the partnership between Cosmos and Vietbay, a Siemens solutions partner. This allowed the company to digitalize the whole part manufacturing process, starting with the CAD model, and right through to the finished part. The previous solution did not offer Cosmos any options for manufacturing particularly complex components which led to a decline in customer orders.

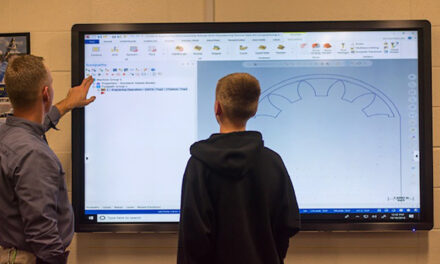

– With synchronous technology, I can easily edit part models while programming in a CAM environment, allowing me to program much faster, says Nguyen Truong Giang, CAM engineer, Cosmos.

– NX CAD/ CAM multi-axis includes a postprocessor library and a tool to help customize postprocessors for our CNC machines. Integrated G-code simulation enables us to verify NC programs without risking damage to the machine tools.

Happy customers and increased productivity

NX allows Cosmos to rapidly machine even complex mold components and to process orders more quickly which has led to a noticeable improvement in customer satisfaction. The integrated CAD/CAM solution has also increased production efficiency by 50 percent, leading to even better production quality while simultaneously lowering costs.