Siemens enables implementation of materials engineering in digital workflow

Plano/Texas, USA. Siemens Digital Industries Software is expanding its Simcenter and Xcelerator portfolio through the acquisition of MultiMechanics, Inc., developer of finite element software. Users will benefit from a solution which can virtually predict failure in materials at an unprecedented level of speed and accuracy. To create the necessary digital twin of materials, material engineering, performance engineering, part design and manufacturing are closely integrated using True Multiscale technology. The implementation of materials engineering in the digital workflow and production, and the resulting cooperation between material developers, manufacturing process developers and part designers enables users to accelerate innovation and reduce costs and development time significantly.

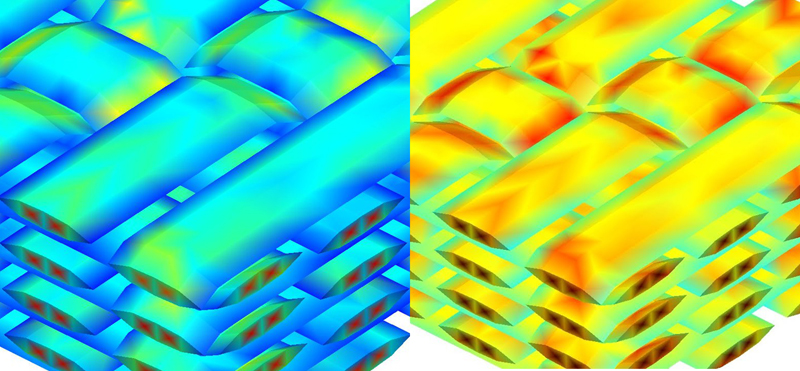

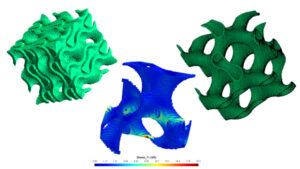

Through its acquisition of MultiMechanics, Siemens is expanding its ability to create a digital twin for its customers. The software developer’s True Multiscale technology supports structural computer-aided engineering for a broad range of materials, including polymers, metals, composites and ceramics. As a result, material failure can be virtually predicted, which enables the use of manufacturing technologies such as injection-molding and additive manufacturing. The digital twin of the material can account for manufacturing variability and imperfections, identify the root cause of material failure at microstructure level, and optimize this structure for best performance.

Through its acquisition of MultiMechanics, Siemens is expanding its ability to create a digital twin for its customers. The software developer’s True Multiscale technology supports structural computer-aided engineering for a broad range of materials, including polymers, metals, composites and ceramics. As a result, material failure can be virtually predicted, which enables the use of manufacturing technologies such as injection-molding and additive manufacturing. The digital twin of the material can account for manufacturing variability and imperfections, identify the root cause of material failure at microstructure level, and optimize this structure for best performance.

– Customers will have the ability to fully exploit the potential of advanced materials to optimize weight and performance in an efficient way that is not possible with classical, test-based approaches, explains Jan Leuridan, Senior Vice President for Simulation & Test Solutions at Siemens Digital Industries Software.