In the middle of the bustling city of Riyadh, Saudi Arabia you can find Al-Rashid Tower. The beautifully polished, tan coloured, concrete and glass surface serves as a beacon for the area, and not the least the  main office of Al Rashid Abetong Co. (ARA). The quality and tone of the building symbolises the quality and craftmanship one has come to expect from an ARA project over the last four decades.

main office of Al Rashid Abetong Co. (ARA). The quality and tone of the building symbolises the quality and craftmanship one has come to expect from an ARA project over the last four decades.

With 5000 Employees, 5 x Precast Factories, and more than 43 years of professional experience in the Saudi Arabian market, ARA excels itself at being one of the heaviest hitters, and most trusted Precast Concrete suppliers in the Kingdom.

With the responsibility coming along with running a behemoth precast company such as ARA, only the best software and IT systems are good enough. In 2020 ARA decided to further strengthen their software packages from StruSoft, with IMPACT Production and Project Manager.

IMPACT Production

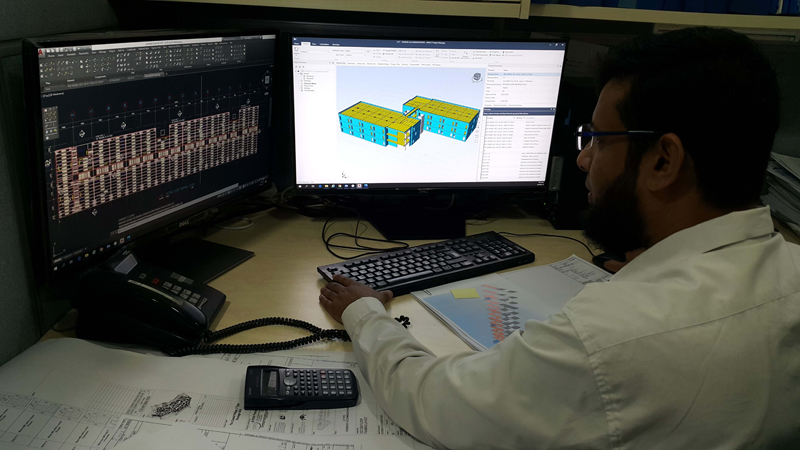

Having utilised the 3D modelling software IMPACT Design over the past two decades, ARA was also looking for intuitive Planning & Tracking software. The choice fell upon IMPACT Production.

– IMPACT Production lets us track every single element from design to site. This element tracking is very important to us as we can make sure to coordinate the elements in the best way possible and keep track of hundreds of deliveries every day. When we plan the elements in IMPACT, or change the status in the Mobile app, the colours change automatically, making it easy to track the process of the project. Says Ingemar Heikenberg, Projects Planning Manager & Asst. Production Manager.

Having an erection crew of almost 1000 people and in some days delivering more than 300 vehicles, traditional planning, such as non-visual spreadsheets, can have a risk of moving the effort away from coordinating the elements and coordinating the planning sheets themselves. Visualising, along with automatic status tracking puts 100% focus on the precast elements, and their status, instead of on the system used for managing them. In 2021, ARA started implementing IMPACT Production and Project from StruSoft. And it is the plan to fully utilize the tools in the system which are amongst others:

• 3D Visual Project management

• 3D visual Cast Planning of all element types

Today and in the future

Today, in 2021 ARA is using the IMPACT system for detailing elements, and is currently implementing planning tools including cast planning, storage, element control and more.

Today, in 2021 ARA is using the IMPACT system for detailing elements, and is currently implementing planning tools including cast planning, storage, element control and more.

In the future, the plan is to implement IMPACT across all detailing disciplines with all precast elements, as well as implement the planning software fully in the field, as well as all factory locations.

StruSoft, together with ARA, is currently organising User training and setup across the organisation; coordinating the implementation of the new software tools in the entire company.

• 3D visual Stack and 3D Transport planning;

• Digital Element controls using mobile phones;

• Disorder and rejection tracking using mobile phones;

• Produced Casts, Storages, and Deliveries using mobile phones;

• Automatic sharable Bills of Materials (BOM) for entire projects.

– We are very happy with the system so far and our continuous work together with StruSoft, says Ingemar Heikenberg.

IMPACT Go – Mobile Element Controls

With IMPACT Production, fully digitised element control (QA) can be realised through using the built in Planning modules; or mobile applications to scan and fill out the controls on Android and IOS mobile devices. ARA has setup more than 40 individual element controls in the software. And the purpose of this is to eliminate paper controls, and replace them with fully digital controls, that will automatically be saved into the IMPACT database and kept in there for reference and measurements for years to come.

With IMPACT Production, fully digitised element control (QA) can be realised through using the built in Planning modules; or mobile applications to scan and fill out the controls on Android and IOS mobile devices. ARA has setup more than 40 individual element controls in the software. And the purpose of this is to eliminate paper controls, and replace them with fully digital controls, that will automatically be saved into the IMPACT database and kept in there for reference and measurements for years to come.

Today and in the future

Today, in 2021 ARA is using the IMPACT system for detailing elements, and is currently implementing planning tools including cast planning, storage, element control and more.

In the future, the plan is to implement IMPACT across all detailing disciplines with all precast elements, as well as implement the planning software fully in the field, as well as all factory locations.

StruSoft, together with ARA, is currently organising User training and setup across the organisation; coordinating the implementation of the new software tools in the entire company.