Siemens software simplifies and automates the development process for plastic molds

Kalamazoo/Michigan, USA. JK Machining (JK) specializes in the design and manufacture of plastic injection molds. The company works primarily in the automotive and medical components industry. JK uses Siemens PLM Software solutions as part of its development process to maintain competitiveness and delivery of highquality molds within short lead times. Amongst other things, this has reduced production times from 22 weeks to 10 and the software solutions also allow frequent changes in design to be completed both smoothly and cost-effectively.

A few years ago, JK decided to replace all the different software systems for designing and manufacturing molds with a single solution. The objective was to install a seamless, automated production process – from design to the finished mold. A decision was made to adopt the NX 3DCAD system from Siemens PLM Software. At JK, the design process for molds starts when customers send in CAD models of the components they require. This is the start of the 3D design process.

A few years ago, JK decided to replace all the different software systems for designing and manufacturing molds with a single solution. The objective was to install a seamless, automated production process – from design to the finished mold. A decision was made to adopt the NX 3DCAD system from Siemens PLM Software. At JK, the design process for molds starts when customers send in CAD models of the components they require. This is the start of the 3D design process.

- Using NX is light years beyond how I used to design molds in 2D, remembers Brian, Mold Designer at JK.

- The mold analysis tools are great – I can easily identify undercuts or places where we need more draft. I can look for thin or thick walls, and automatically determine the total weight of the mold and its center of gravity. The software also produces the bill of materials automatically which saves a significant amount of time.

Simple programming and five-axis machining

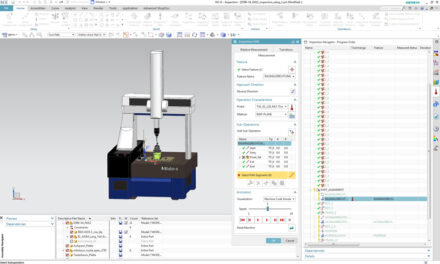

JK can program all the milling process needed to manufacture the mold in NX CAM, saving many hours work on each project as the mold design is fully integrated into NX. One of the key benefits for the JK programmers is the tool tilt control function in NX CAM. This makes machining in five axes extremely easy as the tool automatically converts three-axis tool paths into five-axis tool paths. The open automation and customization tools, which allow NX to be easily adapted to JK’s individual requirements, are also particularly valuable to the business.

JK can program all the milling process needed to manufacture the mold in NX CAM, saving many hours work on each project as the mold design is fully integrated into NX. One of the key benefits for the JK programmers is the tool tilt control function in NX CAM. This makes machining in five axes extremely easy as the tool automatically converts three-axis tool paths into five-axis tool paths. The open automation and customization tools, which allow NX to be easily adapted to JK’s individual requirements, are also particularly valuable to the business.

NX and robotics pave the way to the future

JK’s very positive experience with NX has prompted the business to plan the next stage in its optimization process.

– We are currently considering how we can use robotics to automate the process further. Through automation and continuous improvement with NX, we have been able to reinforce our reputation as a reliable supplier of extremely high-quality tools which allows us to continue to be competitive and grow the business, summarizes Henry Kalkman, President of JK.