Siemens Digital Industries Software announced it has been positioned by Gartner, Inc. in the Leaders quadrant of the 2023 Gartner Magic Quadrant for Manufacturing Execution Systems (MES)1 for the sixth consecutive time. The report states that, “Gartner defines manufacturing execution systems (MES) as a specialist class of production-oriented software that manages, monitors and synchronizes the execution of real-time physical processes involved in transforming raw materials into intermediate and/or finished goods. These systems coordinate this execution of work orders with production scheduling and enterprise-level systems like ERP and product life cycle management (PLM). MES applications also provide feedback on process performance, and support component and material-level traceability, genealogy and integration with process history, where required.”

– We are delighted that Gartner has recognized us as a Leader. We believe this is due to the strength of our vision and that our customers’ experience is built on flexibility, stability and that we have worked to present a cohesive experience to our customers as we grow our portfolio and capability, said Tobias Lange, Senior Vice President Manufacturing Operations Management, Digital Manufacturing, Siemens Digital Industries Software. It’s also great to receive recognition for our work to expand our supply chain coverage through our collaboration with Siemens Digital Logistics.

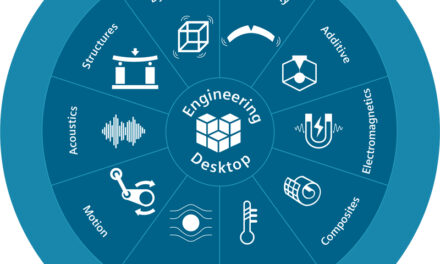

Opcenter Execution MES software from the Siemens Xcelerator portfolio of software and services helps customers to optimize manufacturing operations, accurately reflecting design, engineering and process data in the production of actual finished products. The software help customers to deliver a comprehensive digital twin to the factory floor, accelerating production by digitally linking enterprise systems with automated manufacturing equipment. Opcenter cuts through the complexities of today’s products and production processes to help ensure products are built as planned, on time and cost efficiently, while helping to ensure that floor personnel, raw materials, supplied components and works-in-progress are in the right place at the right time to accelerate production processes.