Siemens PLM Software production simulation increases throughput

Bengaluru, India. The international engineering business Sansera Engineering (Sansera) produces complex, precision-engineered components for the automotive and aerospace industries as well as its own CNC controls (computerized numerical control) and manufacturing lines. Sansera has chosen solutions from Siemens PLM Software to increase production and plant capacities whilst keeping investments in new lines as low as possible.

The business is now able to simulate production scenarios and thus to reduce costs and effort in actual production. At the same time, choosing Siemens software also increases Sansera’s competitiveness, making it a more attractive proposition for new customers.

The business is now able to simulate production scenarios and thus to reduce costs and effort in actual production. At the same time, choosing Siemens software also increases Sansera’s competitiveness, making it a more attractive proposition for new customers.

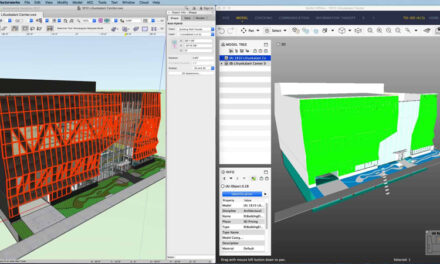

Sansera’s product portfolio includes crankshaft assemblies, rocker arms, gear shifter forks, common rail and connecting rods. Up until now, Sansera has been using 2D layouts for design and construction work. However, these methods were not able to provide sufficiently detailed information for accurate analysis and smooth planning. This led to calculations and evaluations taking a disproportionately long time. In order to improve this process, Sansera decided to optimize this part of the business by using software to simulate the production process. The company chose Plant Simulation from the Siemens PLM Software product portfolio.

Efficient use of manpower

By using Plant Simulation, Sansera is able to simulate complex production scenarios and significantly increase productivity without increasing headcount.

By using Plant Simulation, Sansera is able to simulate complex production scenarios and significantly increase productivity without increasing headcount.

– The simulation tool has helped us to model a balanced production system, identify bottlenecks, and plan manpower optimally, summarizes Sujith S Nath, Asst. Manager – Advanced Engineering at Sansera.

Following the first successful project, Sansera is now also using Plant Simulation to analyse and optimize other existing plants and to validate new production lines. In addition to this, the business is also interested in using the energy analysis functionality of the software in the future.

– Within a year we were able to achieve significant improvements in terms of cost savings on our existing lines as well as on the new ones prior to commissioning.

Following this success, we have decided to use the tool more effectively in the power utilization scenarios as well, explains P. Mahadeva AGM and Head – Engineering at Sansera.