Innovative moldmaker uses Siemens solutions to improve part quality, reduce costs and lead time

Founded in 2013, iMFLUX was created as a wholly owned subsidiary of Procter & Gamble (P&G) as the Ohio-based consumer products giant wanted to improve the technology of plastics processing. P&G saw the need to reduce the cost and lead time to launch new plastic part designs. The company eventually developed a breakthrough new technology that utilized low constant injection pressure, leading to the formation of iMFLUX.

Injection molding requires precision tolerances as plastic is going into tools at up to 20,000 pounds per square inch (PSI) and the gaps between the steel has to resist the plastic from going in between them. The process iMFLUX uses is controlled by pressure rather than velocity or speed. From the moment the press goes to move the screw forward, it is controlling only a set target pressure point. Once it hits that pressure point, it will maintain that pressure until the part’s full and packed out.

The iMFLUX injection molding process involved a specialized controller that enables filling a mold at a lower, defined melt-pressure profile, allowing a variable filling rate that automatically adapts to the part geometry. Advantages include improved part quality, new part and mold design possibilities, sustainability improvements and reduced costs.

Designing a next generation of molds

The process begins when P&G or an external customer sends a mold design or part design concept to iMFLUX. The company then takes the concept from paper sketch through the final qualification of the mold and the part itself. There is pressure to finish the process as soon as possible to meet the customer’s expectations and also start on the next project, avoiding any bottlenecks. As a result, the time from conception to build is condensed.

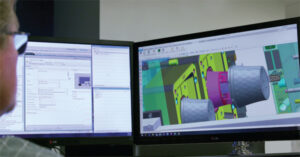

Despite rapidly approaching timelines, ensuring complete accuracy throughout the process is paramount. For iMFLUX, it is extremely costly to find dimensional or mold action errors late in the process due to imperfect mold design and/or mold build process that was not virtually validated. This is where NX software comes into play.

– NX Mold Wizard helps us accelerate the process by doing an analysis on the part for draft checks and wall thickness, says Mark Reagan, mold design engineer, iMFLUX. – It establishes a core cavity split upfront and you can determine whether or not it’s really manufacturable.

NX also enables iMFLUX to pull in predesign mold bases and hardware from the NX Mold Wizard library. As a result, iMFLUX has accelerated its design process as well as its mold building process by 20 percent.

A standalone, wholly owned subsidiary of P&G, iMFLUX takes designs from concept to creation as fast as possible to unlock the speed benefits required by the parent company while still delivering the expected level of quality.

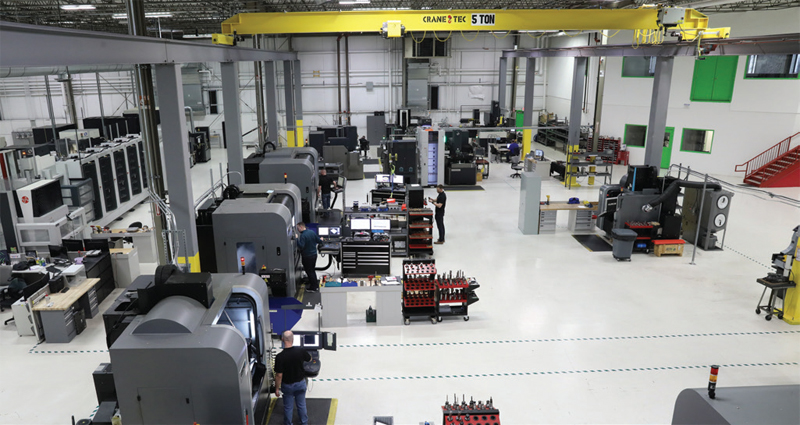

Manufacturing micron-accurate molds

During the company’s infancy, iMFLUX used only the milling functionality of NX CAM to machine some of the mold components. But with the increasingly complex product designs that require sophisticated and high precision mold assemblies to make them, the company decided to bring all the machining disciplines within one computer-aided manufacturing (CAM) system.

During the company’s infancy, iMFLUX used only the milling functionality of NX CAM to machine some of the mold components. But with the increasingly complex product designs that require sophisticated and high precision mold assemblies to make them, the company decided to bring all the machining disciplines within one computer-aided manufacturing (CAM) system.

iMFLUX’s manufacturing team realized that this software consolidation would help them move faster and adapt in the evolving industrial machinery and consumer products space. The company rapidly transitioned to having fixed and multi-axis milling, turning, wire electrical discharge machining (EDM) and sinker EDM all housed within the NX CAM umbrella.

– NX CAM has allowed us to be more competitive by stabilizing our processes, says Jonathan Edwards, CAM programmer, iMFLUX. – This allows us to have first time yields in the 90-percentile range with virtually no scrap.

Indeed, as a result of introducing NX CAM to its processes, iMFLUX can now program a range of CNC machines to make all the mold components (made of different material, such as steel and graphite) using one CAM software. The programmers now house all of the toolpaths into a single part file type, connecting the team and enabling efficient collaboration. NX’s advanced finishing methods help the company to improve part quality and extend tool life, enabling superior parts and satisfied customers.

– Our customers require molds that run millions and millions of parts and to make them as serviceable as possible. They want interchangeable parts, says Brent Huxel, director of design and project management, iMFLUX. – To do that, we’ve got to hit tolerances on the magnitude of microns or tens of a thousandths of an inch.

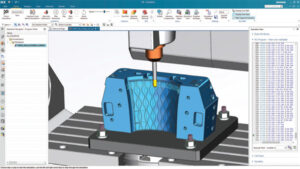

NX CAM provides iMFLUX’s CNC programmers to ability to define an accurate digital twin of their machining setups and processes. The digital replica of the part, vises and the entire machine enable the programmer to easily create complex machining process. As they program operations in NX, they know exactly where the cutting tool is going to be and where the parts are going to be compared to the tool holders and fixtures. They validate the programs using the integrated simulation module that speeds up setup time and eliminates errors and scrap in production.

NX CAM provides iMFLUX’s CNC programmers to ability to define an accurate digital twin of their machining setups and processes. The digital replica of the part, vises and the entire machine enable the programmer to easily create complex machining process. As they program operations in NX, they know exactly where the cutting tool is going to be and where the parts are going to be compared to the tool holders and fixtures. They validate the programs using the integrated simulation module that speeds up setup time and eliminates errors and scrap in production.

Using NX’s postprocessors that are fully customizable, the engineers output production- ready programs and complete shop floor documentation to efficiently run CNC machines, including the latest 3- and 5-axis milling canters, Procter & Gamblelathes, and EDM machines.

Achieving tomorrow’s moldmaking today

The integration of NX CAD with NX CAM automated the end-to-end process from computer-aided design (CAD) part model through mold design all the way to machining molds with extremely high accuracy. NX is a part of the Xcelerator portfolio, a comprehensive and integrated portfolio of software and services from Siemens Digital Industries Software.

– We’ve structured a company and built it of technology that is world-class in part design and in mold design, says Dan Lumpkin, Vice President, Manufacturing, iMFLUX. – What Siemens has done for us, through the suite of technologies they offer, is really help us identify what’s going to help us grow. That’s the kind of partnership we need because we are trying to do things differently. And having a technology partner that understands that,  tailoring their solutions to that, has been a huge asset.

tailoring their solutions to that, has been a huge asset.

Since adopting NX and Teamcenter software, iMFLUX is experiencing high levels of productivity using automated mold processes and can capture, optimize and reuse company knowledge. The company is now enjoying a seamless production process, connecting people, systems and resources. NX and Teamcenter allows iMFLUX to run a flexible operation, enabling the company to meet tomorrow’s needs, today.

– People bet against companies like us a lot. This is an industry that is built on 75 years of doing things one way. We’re challenging all of that and we’re asking people to think differently. When a customer gets that, that’s a pretty rewarding thing.