GKN Aerospace Engines, a business line of GKN Aerospace, needed a better tool to plan and optimize their production process and production equipment investment, a tool that would aid in strategic planning, and handle real life complexity to accurately predict lead times and consider variation. GKN Aerospace needed a new avenue to meet customer delivery expectations and identify any existing problems that could be solved before they became unmanageable. In addition, some value streams share production resources between different products,

which cause crossing material flows. The production complexity and the daily base decision making, impact the lead time, and created an opportunity for a simulation-based approach, to support a continuous improvement. This led GKN Aerospace to believe that discrete event simulation would perfectly support the company’s different initiatives.

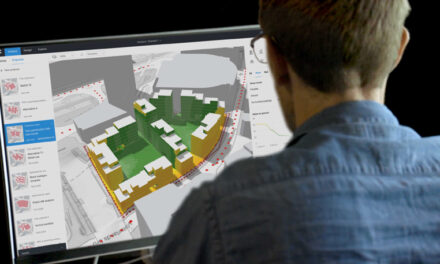

Recognizing a clear need to make their current processes more efficient, while also considering expected future production volume increases, GKN Aerospace decided to conduct a pilot program using Plant Simulation in the Tecnomatix® portfolio. Plant Simulation enables users to define a virtual model of a production plant, with all its characteristics and inter-dependencies, and use it to simulate actual production. Tecnomatix is a part of the Xcelerator portfolio, a comprehensive and integrated portfolio of software and services from Siemens Digital Industries Software.

– We started to use Plant Simulation as we needed a better strategic planning tool to analyze and plan production capacity, says Alexander Hall, MOM-MES Architect, GKN Aerospace Engines Business Line, TI-IS. Given the combination of increased forecasted production volumes and the complexity of our production process, we have realized that the static capacity analysis tools we were using were not accurate enough.

Pilot project takes flight

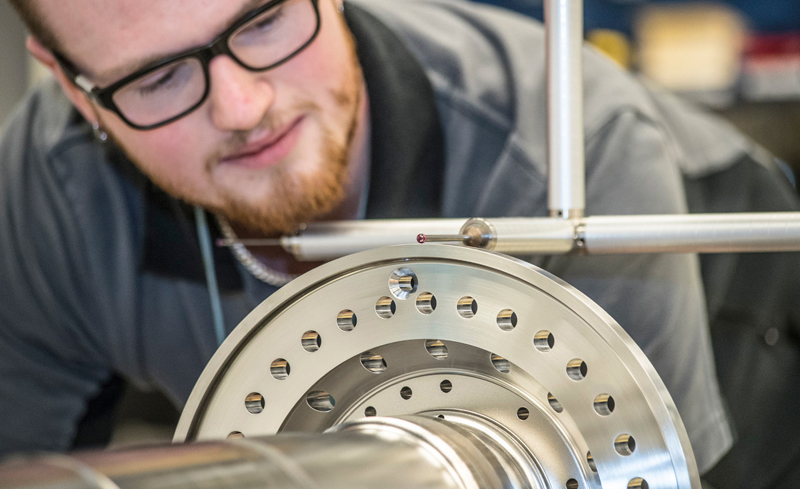

The Plant Simulation pilot project was conducted at GKN Aerospace’s plant in Kongsberg, Norway. This plant was selected for the pilot, as production volumes of their TEC/TRF product family were expected to grow significantly, creating the need to conduct a production analysis and adjust the product system to the new expected volume. The engineers in the Kongsberg plant possessed basic experience with discrete event simulation tools before starting the Plant Simulation project. One of their main goals in this virtual production project was to analyze value streams (value stream is GKN Aerospace’s terminology for a product family and its production process) and identify potential problem areas (bottlenecks, which machines are not being properly utilized, etc.) for improvement.

The Plant Simulation pilot project was conducted at GKN Aerospace’s plant in Kongsberg, Norway. This plant was selected for the pilot, as production volumes of their TEC/TRF product family were expected to grow significantly, creating the need to conduct a production analysis and adjust the product system to the new expected volume. The engineers in the Kongsberg plant possessed basic experience with discrete event simulation tools before starting the Plant Simulation project. One of their main goals in this virtual production project was to analyze value streams (value stream is GKN Aerospace’s terminology for a product family and its production process) and identify potential problem areas (bottlenecks, which machines are not being properly utilized, etc.) for improvement.

Production simulation with Plant Simulation can consider the effect of variability, an important factor that strongly impacts plant performance. In Kongsberg they have planned and unplanned variability. Examples of unplanned variability include machine failures, lack of material from suppliers, and non-conformance. In an environment with a lot of uncertainties, the simulation is a robust production digital twin that takes into account these issues and, in turn, improves decision making in the areas of machine investment and process improvement. Simulation is also a major component of GKN Aerospace’s digitalization initiative.

GKN Aerospace created a simulation model with Plant Simulation, simulated real-life historical production scenarios to validate the model accuracy, and used the model to test future production volume increase scenarios and options. In addition, the capability of Plant Simulation to visualize the production process in a dynamic 3D environment was powerful as it helped GKN Aerospace’s employees to better understand the layout, production process and material flow.

The Plant Simulation pilot project had three main targets: evaluate the applicability of Plant Simulation for GKN Aerospace, produce a simulation template that will ease the use of the simulation tool in other production sites and analyze the expected volume increase in one of the plant product families (or value streams). All three targets were met successfully with Plant Simulation.

The Plant Simulation pilot project had three main targets: evaluate the applicability of Plant Simulation for GKN Aerospace, produce a simulation template that will ease the use of the simulation tool in other production sites and analyze the expected volume increase in one of the plant product families (or value streams). All three targets were met successfully with Plant Simulation.

Another, somewhat unplanned benefit, obtained from the Plant Simulation pilot was that it gave GKN Aerospace a better understanding of how production related data is handled within the company, allowing them to identify several potential areas of important improvements in systems integration and data flows.

Finally, all the insights obtained with Plant Simulation were gained through the creation of a realistic production digital twin model without interfering with the actual production.

– We have a lot of planned and unplanned variability in our plant, says Ragnhild Hansen, technology/project engineer, GKN Aerospace Kongsberg site. – For example, handling non-conformance is an unplanned activity that has a strong impact on our production performance. Plant Simulation helps us analyze the impact of variability on the plant performance, as otherwise it’s almost impossible.

Martin Asp, MOM-MES Architect, GKN Aerospace Engines Business Line, TI-IS says that GKN Aerospace’s production system is very complex and includes variability in both volume and product mix. – It’s a system within a system , with a lot of interdependencies, which makes it challenging to analyze without a suitable tool, he says. As such, we have found Plant Simulation is a tool that can handle this complexity and highlight beneficial insights.

GKN Aerospace also has some thoughts on how they can use Plant Simulation to cope with the new challenges the COVID-19 pandemic presented. For example, the production digital twin created with the simulation can be used for a lot of virtual reviews and reduce face-to-face interaction of employees. Also, the visualization and simulation of a production line helps to understand the production flow, almost as if you’ve visited the line.

– We have learned that Plant Simulation is a great simulation tool that supports our expected production volume change, says Pettersson. It certainly proved its value.