Aachen-based start-up uses Siemens PLM Software solutions for pedelec product development

Aachen, Germany. The e.GO Mobile AG start-up develops and manufactures electric cars. In addition to the e.GO Life car and the e.GO Mover minibus, their portfolio includes the e.GO Kart pedelec. In order to optimize production in terms of time, cost and quality, the start-up is using Siemens PLM Software solutions for their digitalization program regarding e.GO Kart. These provide e. GO Mobile AG with consistent preparation of product information which leads to an increase in manufacturing quality, to time efficiencies of 90 percent in specific areas, and to significant improvements in general in the time/ cost/quality loop.

Aachen, Germany. The e.GO Mobile AG start-up develops and manufactures electric cars. In addition to the e.GO Life car and the e.GO Mover minibus, their portfolio includes the e.GO Kart pedelec. In order to optimize production in terms of time, cost and quality, the start-up is using Siemens PLM Software solutions for their digitalization program regarding e.GO Kart. These provide e. GO Mobile AG with consistent preparation of product information which leads to an increase in manufacturing quality, to time efficiencies of 90 percent in specific areas, and to significant improvements in general in the time/ cost/quality loop.

The whole product development process was digitalized in conjunction with the Complexity Management

Academy and the Rheinisch Westfälischen Technischen Universität Aachen (RWTH Aachen University) WZL machine tool laboratory. In order to be able to structure the project clearly and to digitalize on an itemby- item basis, the product development process was subdivided into six modules: Task management, requirement management, compiling bills of materials, approval process, production process preparation, and change management. For the e.GO Kart e.GO Mobile AG is using the Simulation, NX and Teamcenter tools from Siemens PLM Software to digitally integrate the modules.

Academy and the Rheinisch Westfälischen Technischen Universität Aachen (RWTH Aachen University) WZL machine tool laboratory. In order to be able to structure the project clearly and to digitalize on an itemby- item basis, the product development process was subdivided into six modules: Task management, requirement management, compiling bills of materials, approval process, production process preparation, and change management. For the e.GO Kart e.GO Mobile AG is using the Simulation, NX and Teamcenter tools from Siemens PLM Software to digitally integrate the modules.

Teamcenter as core platform

A core element of the digitalization process was the integration of the bills of materials in Teamcenter which makes product information and data sets available up to 90 percent more quickly. Administering the information centrally in Teamcenter utilizes the principle of a ‘single source of truth’ which ensures there is a central, consistent data filing system. Task management was an equally important item. Teamcenter allows the tasks which have been generated to be automatically forwarded to the relevant employee. This allows, for example, change requests to be quickly and efficiently processed due to the deep integration of NX. Once this is complete, the component release process commences in Teamcenter supported by Workflow.

A core element of the digitalization process was the integration of the bills of materials in Teamcenter which makes product information and data sets available up to 90 percent more quickly. Administering the information centrally in Teamcenter utilizes the principle of a ‘single source of truth’ which ensures there is a central, consistent data filing system. Task management was an equally important item. Teamcenter allows the tasks which have been generated to be automatically forwarded to the relevant employee. This allows, for example, change requests to be quickly and efficiently processed due to the deep integration of NX. Once this is complete, the component release process commences in Teamcenter supported by Workflow.

Consistent software solution

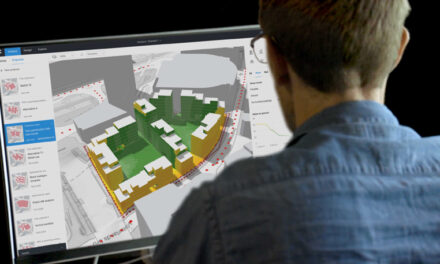

When simulating the e.GO Kart assembly process, e.GO uses the Tecnomatix Process Simulate software which allows the process steps and the relevant resources to be visualized. Videos of the simulations produced in Process Simulate are used as part of employees’ comprehensive training and induction. The consistency of data between the product development view shown in NX and Teamcenter and the relevant product data for manufacturing in Process Simulate allows any necessary changes to the product to be implemented quickly. These changes can be registered by Teamcenter from every area of the business and prioritized and forwarded as required through central registration.

Successful implementation

By digitalizing the development process of the e.GO Kart, e.GO Mobile AG is generating significant improvements in cost, time and quality. The start-up is now planning its next step –complete automation of the change management process. Full automation of the flow of information will allow changes to be implemented even more quickly.