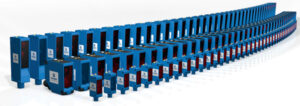

Product lines ready for customizing

For over 35 years, German manufacturer wenglor has developed intelligent sensor technologies, security and image processing systems with state-of-the-art communication standards for the global electronics and semiconductors industry. For more than 20 years, wenglor’s innovative high tech products, created with Solid Edge® software, efficiently have solved both standard requirements and unique customer requests. Solid Edge is a part of the Xcelerator portfolio, a comprehensive and integrated portfolio of software and services from Siemens Digital Industries Software.

In addition to photoelectronic and inductive sensors, wenglor’s core competencies include ultrasonic sensors, fluid sensors, image processing systems, 2D/3D sensors, barcode scanners and safey technology. The company has more than 300 employees in production, administration and management with a permanent workplace at its headquarters in Tettnang, Germany. Today, approximately 950 employees work at wenglor’s various global locations.

In addition to photoelectronic and inductive sensors, wenglor’s core competencies include ultrasonic sensors, fluid sensors, image processing systems, 2D/3D sensors, barcode scanners and safey technology. The company has more than 300 employees in production, administration and management with a permanent workplace at its headquarters in Tettnang, Germany. Today, approximately 950 employees work at wenglor’s various global locations.

The products wenglor develops are used by well-known automotive and food groups, pharmaceutical companies and mechanical engineers as well as materials handling technology companies. The company also serves the beverage, wood, electronic, paper, plastics, textile and packaging industries, which often face complex requirements.

Innovative 3D-CAD on Windows

When Solid Edge was introduced in 1998, wenglor had around 50 employees.

– We wanted to switch to 3D technology back then, says Andreas Müller, development engineer at wenglor. While most systems still ran on Unix operating systems, Windows’ innovative system convinced us with its simple mouse operation. Equally important was the excellent price-performance ratio. wenglor initially purchased three licenses from authorized sales partner T-S Mack in Schönaich, Germany, which later merged to form the Solid System Team (SST).

In 2001, wenglor opened a second production and development site in Sibiu, Romania. While implementing Solid Edge and training, SST’s external support once again proved its worth. Since then, wenglor’s mechanical design department has been using Solid Edge successfully.

When wenglor acquired Mikroelektronik GmbH (MEL), a 2D and 3D sensor technology specialist, in Eching near Munich, in 2013, Solid Edge replaced the existing 3D system SolidWorks. The SST supported the introduction and training of the employees.

– Thanks to Solid Edge, our design engineers could continue using the existing data stock without any problems, says Müller. In the meantime, approximately two dozen floating licenses are in use at all locations.

Product development with Solid Edge

Today, wenglor’s development goals go beyond innovative functions, high quality standards and economic advantages for the automation market. A design of new products, with a targeted selection of resistant and environmentally friendly materials, is as much a part of the company’s strategy as the product range’s comprehensive modularization. In the meantime, existing products can be installed, maintained and exchanged at the customer’s site in a resource-saving manner, resulting in a significant reduction of development time through its modular design.

Today, wenglor’s development goals go beyond innovative functions, high quality standards and economic advantages for the automation market. A design of new products, with a targeted selection of resistant and environmentally friendly materials, is as much a part of the company’s strategy as the product range’s comprehensive modularization. In the meantime, existing products can be installed, maintained and exchanged at the customer’s site in a resource-saving manner, resulting in a significant reduction of development time through its modular design.

In mechanical design, Solid Edge covers the entire spectrum of product development: from the development of metal components to punched and bent parts with and without unwinding, injection molded plastic parts and coordination with toolmakers to the modularization of entire assemblies.

Effectively processing the component inventory

The growing range of components, for example, cannot simply be redesigned – this would mean losing the reference in the enterprise resource planning (ERP) system. On the other hand, the model history cannot be used for upcoming revisions. With synchronous technology, you can simply click on form elements to drag them to the desired position. Or you can add dimensions to edit them. – In this way, we can quickly and easily change old parts while retaining the reference to the ERP system, says Müller.

Simply modernize product lines

Synchronous technology also allows certain design details to be copied and transferred to another project. Designers use this feature to transfer structures from one plastic part to another. For example, when control panels are modernized, entire product lines can be quickly updated by copying and pasting the structures. Synchronous technology allows wenglor’s design engineers to move faster from prototype to series production.

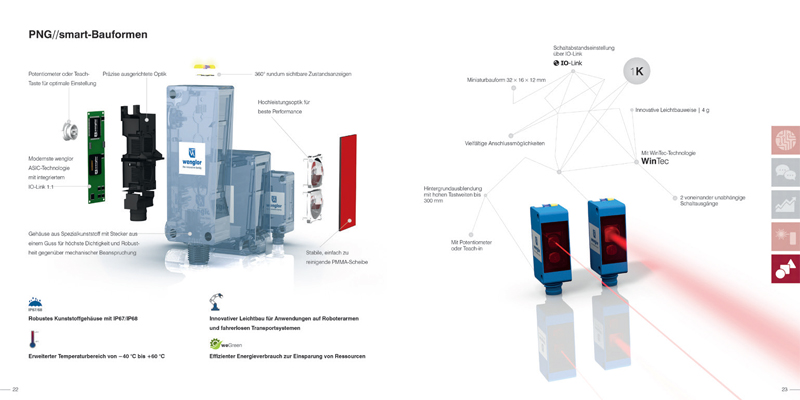

Together with product design and marketing, designers work on the uniform appearance of products across series. – With synchronous technology, we can copy and paste the relevant elements to update them quickly, says Müller. New developments are tested extensively using prototypes. We also use the same powerful capabilities to revise assembly configurations with over 100 variants and different display configurations. For example, the revision of the PNG//smart line of sensors only took half of the time we would have used without synchronous technology.

Quickly edit external data

Solid Edge also accelerates collaboration with external service providers and partners such as toolmakers and 3D printers. Approximately 20 wenglor designer engineers work with Solid Edge. – We recently had to import a 100-pin connector, says Müller. With synchronous technology, we made quick changes to reduce the file size and maintain our assemblies’ performance.

When it comes to manufacturing, the toolmakers send back “negatives” of the designed plastic parts so production-related improvement suggestions can be discussed. – In Solid Edge, we can simply superimpose the two and adjust our design so that model and part will match in the end, says Müller.

Freedom in product development

Synchronous technology also offers possibilities when it comes to generating new ideas. – This is where initial concept models quickly take shape, says Müller. We can change them, check them and often discard them again; it’s all much faster than with conventional methods.

Solid Edge gives users the freedom to combine traditional methods while applying synchronous technology. – To produce product variants cost-effectively, we work with interchangeable inserts in the mold, says Müller. While we are developing the complex geometries of the basic parts with synchronous technology, we can easily control the variants via constraints and the history.

Smooth cooperation

The 3D CAD system, which was selected more than 20 years ago, has continuously evolved despite product development challenges. – We initially viewed synchronous technology with skepticism, says Müller. But in the end, it has significantly advanced our vision. The regular information provided by the Solid System Team, as well as its support and training at the wenglor sites, have paved the way to success. The next project will be replacing the existing ERP interface with the new engineering control center.