Keith Johnston innovates Bruex, Inc.’s manufacturing process to remain competitive as a U.S.-based company serving an evolving market for wooden furniture production.

PROJECT DETAILS

When Keith Johnston took the reins of Bruex, Inc. In Lenoir, North Carolina, from his father Bruce Johnston, Jr., in 2008, he needed to tap into the inventive spirit of his grandfather, Bruce Johnston, Sr., to keep up with 21st century manufacturing processes. Bruce Sr. was the man who patented the process of cold pressing plywood.

According to the patent, which was awarded in 1975, cold-pressing involves taking “one innermost and two outermost veneer sheets, each having a grain and two major surface areas.” A coating of polyvinyl acetate is applied to both major surfaces of the innermost sheets and one of the major surfaces of both of the outermost sheets. After assembling the sheets in a pile, they are pressed into a consolidated composite at room temperature. Part of one of the pressing surfaces is curved. The sheets are pressed for 18 minutes resulting in plywood sheets that are resistant to cracking and splitting during conventional machining processes.

According to the patent, which was awarded in 1975, cold-pressing involves taking “one innermost and two outermost veneer sheets, each having a grain and two major surface areas.” A coating of polyvinyl acetate is applied to both major surfaces of the innermost sheets and one of the major surfaces of both of the outermost sheets. After assembling the sheets in a pile, they are pressed into a consolidated composite at room temperature. Part of one of the pressing surfaces is curved. The sheets are pressed for 18 minutes resulting in plywood sheets that are resistant to cracking and splitting during conventional machining processes.

– The whole business has changed so much. In 2000, there were 32 curved wood manufacturers, now there are only seven, Keith shared. In order to keep competitive in the furniture part supply business, he had to plan and invest wisely in Bruex to adapt to customer needs. His team consists of 20 multi-disciplined people working on the shop floor more efficiently than ever. This is due in no small part to the investment in a top-line 5-axis CNC router and choosing Mastercam as the software to run it.

The shop also has a 3-axis router, six radiofrequency machines, and rows of cold press machines. In recent years, Keith has witnessed a shift in the furniture making business in that the contours and shapes of the furniture are becoming more detailed and varied, requiring different cutting and boring operations.

Programmer Dennis Garcia said that grain direction is the most important consideration when cutting the veneers. “When we run counterclockwise, we get a better finish on plywood than running clockwise because of the way the spindle rotates and the direction of cut,” he said. The 5-axis machine allows them to step more difficult curved plywood parts.

Programmer Dennis Garcia said that grain direction is the most important consideration when cutting the veneers. “When we run counterclockwise, we get a better finish on plywood than running clockwise because of the way the spindle rotates and the direction of cut,” he said. The 5-axis machine allows them to step more difficult curved plywood parts.

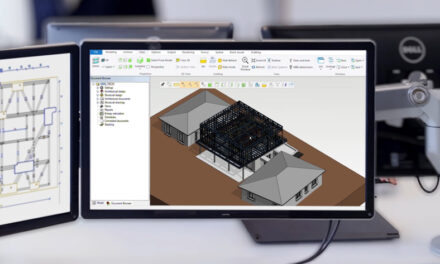

According to Dennis, the CAD/CAM software is the brains of the whole operation. “If we didn’t have the software, we’d be out at the machine with a tape measure and calipers trying to type everything by hand. Now, it’s a whole lot quicker and easier to keep these machines running.” He uses many of Mastercam’s Surface and Solids functions. Bruex also uses MoldPlus for Mastercam, a 3rd party solution that allows programmers to create and manipulate complex curves and vectors for 5-axis trimming and a Master3DGage using Verisurf software that provides a fully automated 3D inspection process within the Mastercam user interface and can be used to reverse engineer parts.

Dennis favors 3-axis toolpaths for day-to-day jobs, using Mastercam Router’s suite of tools, including Curve/Drill 5-axis which cuts a 3D chain on surface edges and simplifies the creation of 3- to 5-axis drilling output for holes within a part. The Multiaxis solution allows him to perform 5-axis multisurface operations such as roughing and swarf fanning, and 4-axis, rotary axis, and roll die programming.

One of the company’s customers has a standing order for an X-pitched base for a chair ottoman that has a certain pitch to it to balance the assembly. Bruex builds the plywood to the customer specifications, then edges and splits the plywood on bandsaws before heading to the saws with dado blades to notch out the boards. However, the dado blade could not be used to notch one of the boards, requiring them to go back to the bandsaw to cut the notches. There needed to be a high level of consistency because the assembly was the base product for the ottoman.

– If my saw wasn’t accurate, it wouldn’t sit on the floor properly, increasing the need for more prepping and sanding, Keith said. Dennis digitized the whole operation on the 3-axis router. Keith continued,

– The accuracy is dead on. Every single one of the assemblies is coming out exactly the same. He’s making the notches where they fit into each other. Everything is consistent and tight.

Now crews are free to produce the side and back rails, and the top back rails of these furniture pieces. Dennis plans to eliminate the overhead pin router and spindle carver, leaving just three steps of the original nine left to do separately.

Now crews are free to produce the side and back rails, and the top back rails of these furniture pieces. Dennis plans to eliminate the overhead pin router and spindle carver, leaving just three steps of the original nine left to do separately.