Solution 401/402

Predict behavior of parts or assemblies with nonlinear contact, nonlinear material or large deformations.

Benefits

Reduce design risk by using simulation to save time and cost compared to physical build-and-break test cycles

Accelerate your innovation through rapid iteration and numerous “what-if” studies

Use the same models already built and analyzed linearly with NX Nastran – Basic

Improve confidence in final designs by virtually investigating your product’s performance under all possible operating conditions

Obtain more accurate solution results than linear analysis when standard linear assumptions are not valid

Summary

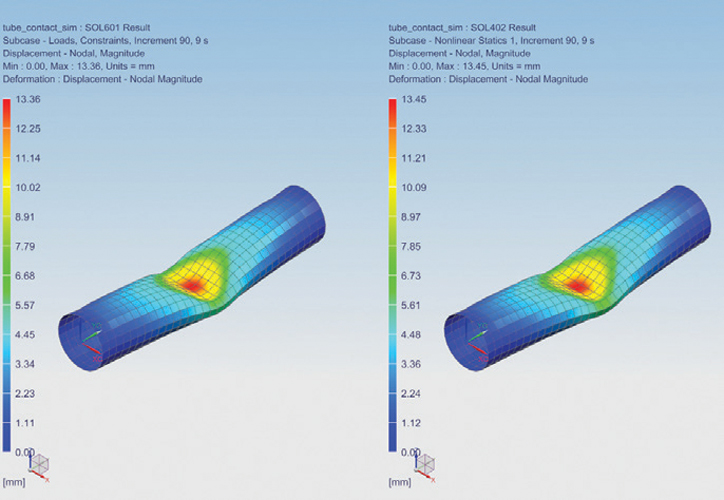

The NX Nastran Multistep Nonlinear software solution enables you to analyze models with nonlinearity from contacting parts, material property nonlinearities and/or geometric nonlinearities (that is, large deformations and large strains). This solution is an add-on module of NX Nastran – Basic in either enterprise or desktop versions. The Multistep Nonlinear license provides access to both the SOL 401 Multistep Nonlinear solver and the SOL 402 Multistep Nonlinear Kinematic solver. Both use nonlinear implicit methods based on similar formulations. SOL 401 is implemented in the standard NX Nastran architecture and leverages the same code base as other NX Nastran solutions. SOL 402 is an integration of the well-known and highly regarded LMS Samtech Samcef solver into NX Nastran. Either solver can be used to solve a large class of nonlinear solutions and give very similar results. Other classes of nonlinear solutions may be better solved using one or the other.

Users can refer to the NX Nastran documentation to see which solver may best support their applications or consult with the Siemens PLM support organization.

The multistep structure of the SOL 401/402 solutions provides powerful and flexible solution capabilities. Multistep solutions are important in nonlinear simulation because unlike linear simulations, the sequence of loading affects the results. With multistep capability, users can step through different types of solutions all in one solution run. For example, you can apply bolt preloads with contact definitions in the first step, follow with a set of service loads in the next step, and then compute modes about the deformed loaded condition in still another step. Any number and type of steps are allowed. This gives users the ability to simulate assembly sequences or modal frequency effects from loading and contact, and to apply pre-stress before starting a dynamic solution.

There are many reasons for users to go beyond linear solution methods and look to nonlinear. For example, geometric nonlinear effects need to be simulated when stiffness properties or loads change significantly as the result of deformation. Analysis of snap-through buckling is an example in which geometric nonlinearity effects are important. Material nonlinear effects should be modeled when the material properties cannot be considered linear for the loading conditions considered. Example usages are for analyzing hyper-elastic (rubber) materials or analyzing metals that exhibit plastic behavior because they are stressed beyond yield limits. Advanced contact capabilities allow you to simulate surface contact using either shell or solid elements. Many mechanical simulations involve parts coming into contact under load. With the advanced Solution 401/402 surface contact capabilities, the solver determines the extent of surface contact and load transfer across the contacting surfaces as part of the solution.

Both NX Nastran Multistep Nonlinear solutions also have very robust solution algorithms and efficiently obtain converged solutions for some of the most difficult and intractable nonlinear models. The input and output formats for SOL 401 and 402 are also very similar and it is very easy to set up a Nastran model to run for either solution.