Swiss team designs electric race car for Formula Student with Siemens PLM Software

Zurich, Switzerland. The Academic Motorsports Club Zurich (AMZ) was the first Swiss team to take part in Formula Student and, since then, they have designed a new race car every year with several hundred new parts. The team also develops a new prototype every year which the students take to the grid. The young engineers make use of solutions from Siemens PLM Software to complete the design work, checking and technical documentation for the new vehicle. Since 2010, the AMZ team has only entered purely electrically driven race cars for the races, and in 2016 they set a new world record with their ‘Grimsel’ car by accelerating from 0 to 100 kilometers per hour in 1.513 seconds.

Zurich, Switzerland. The Academic Motorsports Club Zurich (AMZ) was the first Swiss team to take part in Formula Student and, since then, they have designed a new race car every year with several hundred new parts. The team also develops a new prototype every year which the students take to the grid. The young engineers make use of solutions from Siemens PLM Software to complete the design work, checking and technical documentation for the new vehicle. Since 2010, the AMZ team has only entered purely electrically driven race cars for the races, and in 2016 they set a new world record with their ‘Grimsel’ car by accelerating from 0 to 100 kilometers per hour in 1.513 seconds.

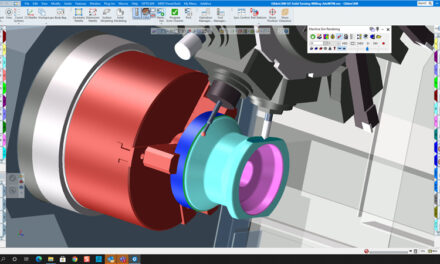

Formula Student was set up in 1981 by the Society of Automotive Engineers and is the most popular competition of its type for young engineers. Over 600 teams from universities throughout the world compete in 18 races every year with race cars they have built themselves. One of them is the AMZ team which consists, on average, of 35 members. Several hundred components are designed for each car, including tires and electric motors. “We develop our motors for the specific requirements of our vehicle. This allows us to achieve maximum performance density: The four motors each have an output of 50 HP (horse power) and weigh barely three kilograms,” says Nirushan Arumugam, CEO of AMZ. The core software for the design process is NX, a comprehensive engineering software package from Siemens PLM Software’s solutions portfolio.

Software modules make design easier

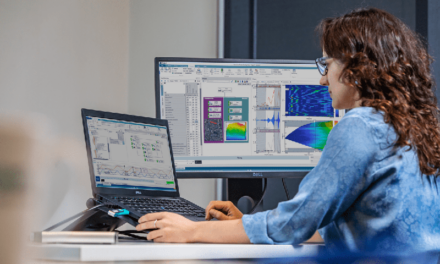

Although the current team is always supported by previous members, the complete new development of a race car in just a few months is an enormous challenge. The Siemens PLM Software solutions, which make it possible to create a digital twin of the race car, make the young engineers’ work much easier. “The deep level of integration of all NX solutions with Siemens PLM Software is a significant benefit for us,” explains Arumugam.

Although the current team is always supported by previous members, the complete new development of a race car in just a few months is an enormous challenge. The Siemens PLM Software solutions, which make it possible to create a digital twin of the race car, make the young engineers’ work much easier. “The deep level of integration of all NX solutions with Siemens PLM Software is a significant benefit for us,” explains Arumugam.

“We can start Simcenter 3D in the NX environment. The fact that we do not have to familiarize ourselves with different user interfaces saves us a great deal of time and reduces errors.” In addition to the NX functionality for computer-aided design (CAD), AMZ also makes great use of Simcenter modules which allow the team to check the design over the race car’s entire development process. This is particularly important as the light but powerful vehicle can push the limits of what is physically possible during a race. “We use the Simcenter 3D Motion software for multi-body simulations and carry out strength analyses with NX Nastran as well as flow simulations with the Star-CCM+ software,” continues Arumugam. All the results are brought together in NX and can be retrieved from there by everyone involved in the project. This allows the team members to create the optimum aerodynamics and geometry for their race car.

Harsh testing conditions

The teams take part in a wide range of competitions. In addition to drag races, track races and autocross qualifying, the vehicles must also successfully complete an endurance run of 22 kilometers as well as static evaluations. In the latter, the teams present their vehicles and their development work to an independent jury which assesses the design, business and financial planning as well as production. Between 2013 and 2016, the AMZ team won eight of the 16 competitions and, in 2016, set a new world record of 0 to 100 kilometers per hour in 1.513 seconds with the ‘Grimsel’ car. By comparison, the quickest production car needs 2.2 seconds

The teams take part in a wide range of competitions. In addition to drag races, track races and autocross qualifying, the vehicles must also successfully complete an endurance run of 22 kilometers as well as static evaluations. In the latter, the teams present their vehicles and their development work to an independent jury which assesses the design, business and financial planning as well as production. Between 2013 and 2016, the AMZ team won eight of the 16 competitions and, in 2016, set a new world record of 0 to 100 kilometers per hour in 1.513 seconds with the ‘Grimsel’ car. By comparison, the quickest production car needs 2.2 seconds