Solar cells, batteries, aerodynamics, and electronics. These technologies might be the path to sustainably meeting the majority of our energy needs, using only solar power. But is it possible to create race cars that use the sun as their only fuel source? The answer is: yes! And to do so, the Agoria Solar Team is partnering with Materialise yet again.

Since 1987, teams worldwide have explored the Australian Outback in a thrilling and unique solar car race. The World Solar Challenge is the Formula 1 of solar cars. Representing mainly universities, these teams create cars powered only by the sun. They will never be plugged in. This means that these cars are basically solar panels on wheels that will go 120 km/hr.

But this challenge goes way beyond just a race. With future generations in mind, they’re testing the boundaries of science. In fact, the main driver of this event is the passion of young people that not only dream of finding cleaner and greener ways of racing but also work hard on making those dreams come true. After all, when you’re competing with 44 teams from 21 different countries, you know you have to push the envelope and take your car to the edge of engineering. The lighter and more aerodynamic it is, the farther and faster it goes. Efficiency is the keyword here.

But this challenge goes way beyond just a race. With future generations in mind, they’re testing the boundaries of science. In fact, the main driver of this event is the passion of young people that not only dream of finding cleaner and greener ways of racing but also work hard on making those dreams come true. After all, when you’re competing with 44 teams from 21 different countries, you know you have to push the envelope and take your car to the edge of engineering. The lighter and more aerodynamic it is, the farther and faster it goes. Efficiency is the keyword here.

New season, new challenge

Unfortunately, the current pandemic and the severe travel restrictions in Australia meant that this race was canceled earlier this year, a setback for solar teams from around the world, who quickly joined forces to look for a new challenge. In October 2021, the Agoria Solar Team — a crew of 20 ambitious engineering students from the KU Leuven University— will participate in the Solar Challenge Morocco, a brand-new solar race across the Moroccan Sahara.

Student teams from universities around the world will compete in a 2,500-kilometer drive along the foothills of the Atlas Mountains. And it is precisely after this mountain range that the Belgian new solar car, the BluePoint Atlas, is named.

This season’s highlight feature? The new machine has only three wheels and a unique, streamlined bullet shape. This streamlined shape ensures minimal air resistance during driving, ultimately resulting in greatly reduced energy consumption of the solar car.

There is also another novelty. For the first time this year, the team built its own electric motor. This self-designed engine has an efficiency of 98%, higher than any motor available on the market.

The Belgian Agoria Solar Team partners with Materialise

Since the beginning of the summer, the team of engineering students have been working on designing their new solar car with the primary goal of competing in a new challenge alongside solar teams from other countries. The experienced team plans on keeping up with the good work of 2019 when they were crowned champions. Back then, they also partnered with Materialise to design their battery case.

As 3D-printed products have proven repeatedly throughout the years, AM is the perfect method to create a lightweight material with organic  shapes that traditional manufacturing cannot construct. – There are three different moments in which 3D printing is fundamental for us. Firstly, the prototyping phase, then the validation moment in which we make sure everything is working according to our calculations. Lastly, the car parts, explains Bart Depredomme, Head of Mechanics at the Agoria Solar Team.

shapes that traditional manufacturing cannot construct. – There are three different moments in which 3D printing is fundamental for us. Firstly, the prototyping phase, then the validation moment in which we make sure everything is working according to our calculations. Lastly, the car parts, explains Bart Depredomme, Head of Mechanics at the Agoria Solar Team.

This year, Materialise helped the team develop two main car parts: the battery case and the steering handle. According to Bart Depredomme, the expertise of Materialise is a game-changer in the outcome of the project: – The battery case needs to allow airflow, and this means it has a complex design. The steering handle also needs to be made from a flexible material that allows it to be ergonomic. Materialise has helped us develop ideas on how to improve the designs and make our car durable and trustworthy.

Indeed, when you’re competing in a two-thousand-kilometers endurance race, anything is possible, and the slightest driving or even engineering mistake can put everything at risk. So, making sure that you have reliable suppliers is fundamental when driving for five days in the middle of the Sahara Desert.

In the last race, a competing team had their battery case catch fire during the competition. Needless to say, nobody wants to experience an accident in a 130-kilo solar car made of carbon fiber and a combustible battery, so safety is paramount. – We have to be extra careful, not only for safety reasons but also because it would waste our time to stop and fix the car part. That is why we choose our partners cautiously, explains Depredomme.

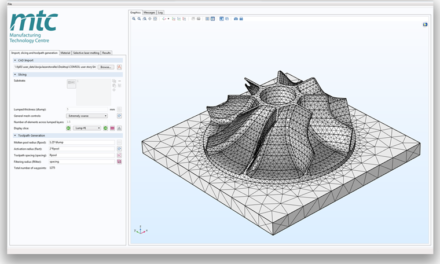

He also points out how much time they were able to save by using Materialise’s software for build and data preparation, Magics.

– The software makes everything easier and faster. With it, we could make sure that all parts were printable and with high-quality capabilities, avoiding costly build failures, describes the Agoria Solar team member while celebrating the successful outcome of the partnership.

The Solar Team will participate in the international racing challenge on the African continent this fall. We wish them the best of luck and look forward to cheering on the BluePoint Atlas!

Av Cecilia Kashiikene

www.Materialise.com