Automotive supplier opts for Siemens PLM software for the development of assembly systems

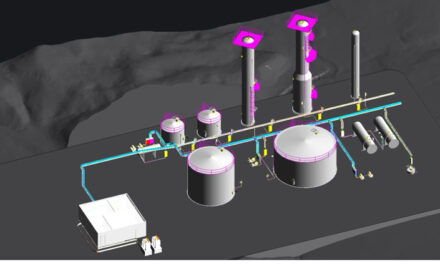

Based near Turin, Italy, Comau is a world leader in industrial automation. To optimize its engineering and integration processes and to simplify the validation of plant equipment, Comau has turned to a completely virtual commissioning solution from the Tecnomatix portfolio from Siemens PLM Software. This allows the complex plants to be fully simulated and tested before actual commissioning, improving quality and time-tomarket.

Turin is a town of almost one million inhabitants in the north-west of Italy. The multinational corporation Comau has its headquarters here – a leading business in industrial automation, supplying, amongst other things, assembly systems and indoor robots to many sectors. The Body Assembly (BA) division at Comau focuses on developing concepts and commissioning control systems for vehicle body construction lines. To bring continuous improvement to their assembly line designs and to increase safety and efficiency, the Comau experts in Turin work with their colleagues throughout the world using software solutions from Siemens PLM Software.

Efficient troubleshooting is required

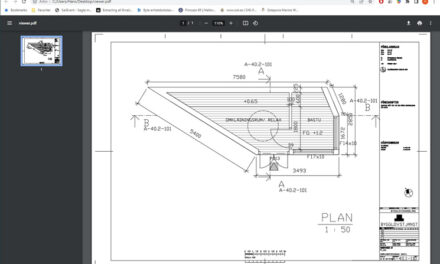

In 2009, the BA division launched a pilot project to enhance quality and time-to-market by improving engineering and integration processes and to validate plants from CAD models, the so-called “virtual debug” (virtual possibility of diagnosing and locating errors).

Comau invited Siemens PLM Software on board in 2011 as part of a wider pilot project on the implementation of a virtual debugging process.

– Comau builds enormous plants and it was not possible for us to assemble and test everything during installation, says Francesco Matergia, Engineering and Automation Systems Director at Comau.

– Until now, we were only able to simulate a few areas and functionalities on a line or to test only a few of the hundreds of robots used in a plant.

– The opportunity to test had to be extended to the whole plant and all its component parts in order to capture valid and relevant results.

Simulation of all functions

Siemens PLM Software offered Comau a solution from the Tecnomatix portfolio for complete, virtual commissioning based on their requirements. In addition to the mechanical resources on a line (machines), virtual commissioning with Tecnomatix also integrates the functionalities of programmable logic controllers (PLC). This provides a simulation of the whole line and all its operations. Francesco Matergia’s reaction was suitably positive. Significant improvements were quickly to be seen with

respect to satisfaction and efficiency.

The time required to achieve a specific level of performance was considerably reduced.

– We are already looking in different directions and the Tecnomatix experts are working closely with us to extend the solution to other sectors and functions which do not necessarily have anything to do with design.

– In addition to that, there is a great deal of benefit to be had from Siemens PLM Software’s standardized processes in the analysis and calculation phases.

– This allows us to react rapidly to customer inquiries and generate cost proposals and quotations quickly.

In order to be able to simulate and test complex assembly lines for vehicle body construction before commissioning, the Italian industrial automation specialist, Comau, has opted for software solutions from Siemens PLM Software.