Heat exchanger increases cooling fan efficiency with Siemens solution

Founded in 1940, Bronswerk Heat Transfer BV specializes in the design and production of heat exchangers and condensers, air-cooled coolers and comprehensive systems. Focusing on high-quality, innovative solutions for heat exchanger issues, Bronswerk Heat Transfer BV has offices and locations in the Netherlands, the Czech Republic and Russia, employing approximately 300 people.

Bronswerk Heat Transfer BV designs, produces, and delivers industrial systems of (shell and tube) heat exchangers, cooling equipment, a-frame condensers, air-cooled Bronswerk Heat Transfer BV was recently tasked with increasing the efficiency of cooling fans at large industrial plants while simultaneously decreasing the noise emitted from those fans. In these facilities, fans as large as 33 feet move air across bundles of coils inside a gas or oilfield cooling system.

Bronswerk Heat Transfer BV designs, produces, and delivers industrial systems of (shell and tube) heat exchangers, cooling equipment, a-frame condensers, air-cooled Bronswerk Heat Transfer BV was recently tasked with increasing the efficiency of cooling fans at large industrial plants while simultaneously decreasing the noise emitted from those fans. In these facilities, fans as large as 33 feet move air across bundles of coils inside a gas or oilfield cooling system.

Dozens, even hundreds, of fan systems may be needed to cool the gas or oil, along with untold megawatts of electrical power to run these fans. Fan noise is as important as cost issues when it comes to regulations as large industrial plants are subject to stringent noise regulations. Fans traditionally used in this environment deliver a maximum efficiency of about 50 percent. What would happen if that efficiency could be increased to 80 percent? Or even more? Fewer fans could do the same work with less energy, less noise and lower operational costs. With this vision, the design engineering team at Bronswerk Heat Transfer BV set out to create a new generation of air-cooled cooling systems that would solve age-old problems.

Choosing Simcenter FLOEFD

Those Bronswerk Heat Transfer BV design engineers selected Simcenter FLOEFD software to develop an oil and gas industrial-plant cooling fan that is more energy efficient, quieter and lighter weight than its predecessors.

Those Bronswerk Heat Transfer BV design engineers selected Simcenter FLOEFD software to develop an oil and gas industrial-plant cooling fan that is more energy efficient, quieter and lighter weight than its predecessors.

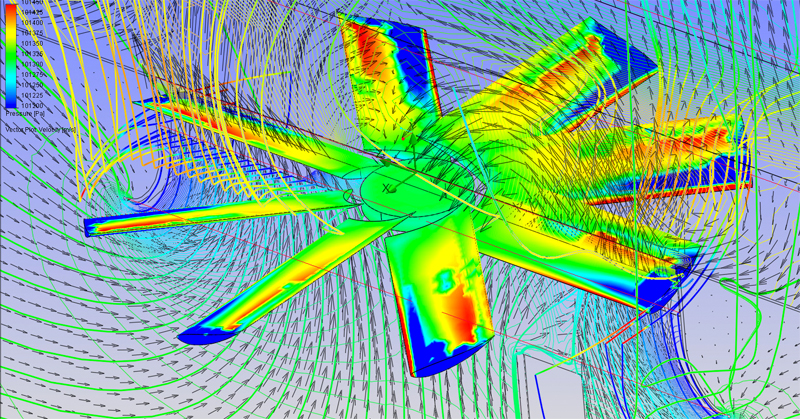

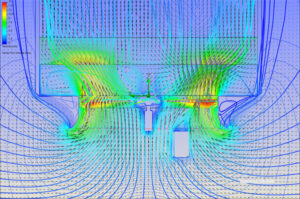

Simcenter FLOEFD enables analysis and validation that are impossible solely with physical measurements. Simcenter FLOEFD is a proven concurrent 3D computational fluid dynamics (CFD) toolset for analysis and validation of their design updates. Simcenter is part of Xcelerator, a comprehensive and integrated portfolio of software and services from Siemens Digital Industries Software.

Breaking industry records

The new Bronswerk Heat Transfer BV cooling solution the design engineers developed includes fans and housings that take their technology cues from gas turbines, aircraft wings and a generous helping of homegrown creativity. Simcenter FLOEFD quickly and accurately validated the practicality of these creative touches. In addition to their purely quantitative output, the CFD simulations helped Bronswerk Heat Transfer BV explore bold ideas without risking project budgets and schedules.

Bronswerk Heat Transfer BV’s Whizz-Wheel-based cooling systems, which are documented to increase performance by up to 30 percent, reduce plot space and reduce noise and power consumption, are now breaking all industry records for energy efficiency, noise reduction, and weight savings.