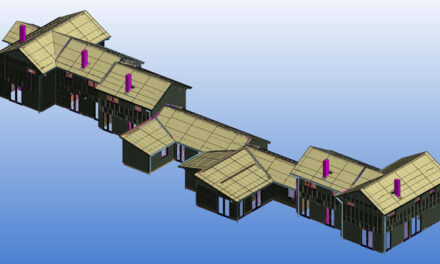

Aqua free Industries, a leader in innovative drinking water hygiene solutions, marks a new chapter with the inauguration of its state-of-the-art facility in Lommel, Belgium. This cutting-edge site not only sets new standards in research and development but also doubles the company’s production capacity to meet the growing demand for advanced membrane filters. This strategic move reinforces  Aqua free Industries’ commitment to delivering highly specialised filter solutions to discerning customers worldwide through tailored OEM partnerships.

Aqua free Industries’ commitment to delivering highly specialised filter solutions to discerning customers worldwide through tailored OEM partnerships.

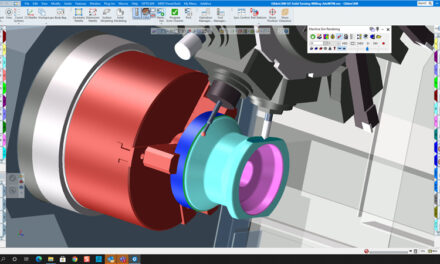

As a trusted partner to the aviation and healthcare industries, Aqua free Industries once again demonstrates its innovation with the PuriFLY Aircraft Potable Water Filter. This new filter technology features a specially developed membrane that removes 99.99999% of all bacteria, tested according to the stringent ASTM F838 standard for bacterial retention. An integrated activated carbon element further reduces chlorine, taste, odours, organic compounds, and heavy metals.

With a maximum flow rate of 10 l/min and an operating pressure of up to 5 bar, the PuriFLY filter delivers exceptional performance. Comparative tests show significantly reduced pressure loss compared to conventional filters, ensuring efficient use. The PuriFLY filter is compatible with existing filter housings, allowing for seamless integration. It represents the pinnacle of hygiene standards in aviation, marking another milestone in the development of advanced filter solutions.

In close collaboration with Lufthansa Technik, Aqua free Industries has developed a groundbreaking two-stage filter system that significantly improves onboard water quality while reducing maintenance requirements. The PuriFLY filters integrate effortlessly into existing systems, such as the General Ecology series (AC3), and offer outstanding flow rates with minimal pressure loss – a  true advantage for the aviation sector.

true advantage for the aviation sector.

– Our new facility in Belgium enables us to respond more flexibly to the needs of our customers while guaranteeing the highest hygiene standards, says Gregor Krey, Managing Director of Aqua free Industries.

– The successful development of the two-stage filter with Lufthansa Technik is a perfect example of our commitment to OEM partnerships. Such collaborations highlight our ability not only to deliver innovative products but also to create bespoke solutions that make a real difference. With its new Lommel facility and a strengthened focus on global OEM partnerships, Aqua free Industries is well-positioned to lead the market in membrane filter technology. The company remains dedicated to ensuring water safety for critical applications, securing its position as a global leader in this field.