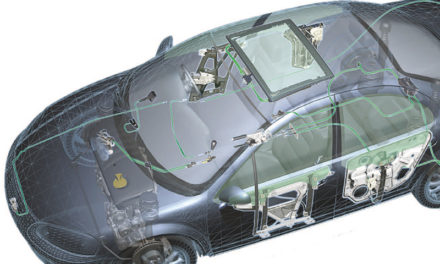

The Internet of Things is a concept the folks at Pacon Mfg, Inc. take seriously. The company has spent several years optimizing its digital-to-physical manufacturing of high-complexity, precision components. The Livermore, California company serves mostly OEM customers and Defense Primes in the development of electronic and motion control components by manufacturing precision motion components for semiconductor equipment, microwave and structural components for Space and Defense, and electro-optical system components for life science equipment.

PROJECT DETAILS

Pacon CEO, Steve McClure, says his company works under an over-arching approach they call “Precision Machining 4.0.” He defines it as “Digital-to-Physical manufacturing through our operationally comprehensive implementation of lean manufacturing principles with Industry 4.0 technologies. The approach spans the selection of machine tools, how we use them to change the manufacturing process, and our selection of software on the digital-physical side of that, particularly digital. Precision Machining 4.0 isn’t just how we operate, McClure said, It’s what has made us the company we are today.

– Keeping our focus on digital-physical has been key in meeting our customers’ expectation of quality, especially as we went from 3-axis machines to 5-axis, McClure said. (In 2015, Pacon moved to 5-axis aiming to decrease scheduling complexity and to simplify set-ups while minimizing yield loss.)

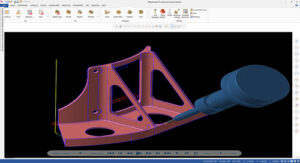

Since 2000, the company has used Mastercam® CAD/CAM software from CNC Software, LLC, (Tolland CT) for milling. When they moved to 5-axis, they considered alternatives but chose to stay with Mastercam, in part because they didn’t want multiple platforms, but also because they thought that new features of the software would be helpful in giving PACON an advantage. That’s exactly what happened.

– As we took on 5-axis machining, we found new sets of features in Mastercam to help us do those new things, said McClure. Keeping in mind that ours is a digital-physical process, McClure said, on the front end, we want to do as much as possible in the software. Given that our customers usually give us a STEP file, with Mastercam’s integrated SOLIDWORKS reader we can program right off the solid file in the software, which really streamlines the time. So, already in the digital phase, we’re improving productivity. Pacon has four seats of Mastercam Mill including full 5-axis modules on at least two of the seats.

When Pacon first implemented 5-axis machining, that unit could hold 30 tools which, McClure pointed out, were enough for one part. Today, their larger cell holds 313 tools per machine with roughly a third of them allocated to standard tools. As programmers add tools for new applications, they eventually become standard and are uploaded into the software’s Tool Library for future parts. The high-mix shop sees lot sizes ranging from one part to hundreds of parts per week and sought to find a way to standardize and build a library for its fixturing pieces.

– It made simulation a lot easier because we could build the library and weren’t building a new fixture for each part anymore, said McClure.

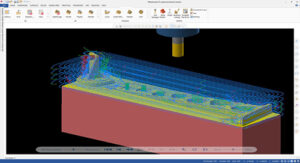

On the manufacturing end, McClure reported that at least two of the software’s major features have become Pacon’s go-to’s: Mastercam’s Dynamic Motion technology and the OptiRough toolpaths.

– We make several highly complex parts for satellite work, structural parts that hold parts of the satellite together. These things have complex angles because whatever it is holding up must have this weird twist to it. And they have multiple angles, so a bracket, for example, may be holding multiple entities together, said McClure.

The parts need to be as light as possible. Their geometries feature a lot of wavy pockets and complex angles that can be machined in one set up on a 5-axis machine. The team has found that the software’s OptiRough toolpaths which use the entire flute length of the tool, but a small percentage of the tool’s diameter on the first cut, followed by several successive shorter cuts that bring the part into the shape desired, works well. They allow large amounts of material to be roughed out, yielding a near net shaped part. Measuring 1- x 1- x 1- to 5- x 10- x 23-in., the brackets must be machined to tolerances of +/-0.003-inches. Material is initially roughed out using 2D Dynamic Mill, Area, and Peel toolpaths.

– We use the OptiRough toolpaths for roughing at 0.010- to 0.15-inches away from the finish size, said McClure. For finishing, they program 2D Facing, Pocketing, Contour, Dynamic Contour, and Peel toolpaths followed by 3D Horizontal and Parallel toolpaths.

Pacon is certified by this customer for digital product development (DPD) which qualifies the company to use the solid or step file from the customer to make a part according to the “rules” put in place by the latter.

– When we get the drawings of the brackets, many times there are radius intersections that are not friendly,” explained McClure. You have weird cutting corners for the 3D surfaces, and we end up having to do contouring toolpaths to blend them. Traditionally, people will pick a tool and say ‘this is the radius it’s going to be’ but then you end up with something that is non-conforming to the STEP or solid file, and it wouldn’t be precise. That’s a problem for our customers because model strength and weight are on all of their drawings and any deviation of that model means there’s a deviation with the simulation.

– To run a lean manufacturing operation, McClure said, Pacon has had to reset a lot of its past practices. Knowing the end goal is enormously valuable, he added. And ranking the order of your issues and solving one at a time is fundamental.

Customer Quote

– Given that our customers usually give us a STEP file, with Mastercam’s integrated SOLIDWORKS reader we can program right off the solid file in the software, which really streamlines the time. So, already in the digital phase, we’re improving productivity.

Steve McClure, CEO, Pacon Manufacturing, Inc., Leland, NC