At the Press Conference ahead of the Hannover Messe 2018, concrete implementation of the Industrie 4.0 concept in the Digital Enterprise was presented in the form of six Expert Talks relating to selected sectors of industry. As part of our series dealing with the expert topics, this article looks at “Digitalization in the Brewery Industry”.

Traditionally, beer was simply brewed locally using age-old hand crafting methods. Today, the use of wooden vats and open fires has become practically obsolete. Modern breweries make use of high-tech plants which will provide the assurance of a consistently high standard of quality.

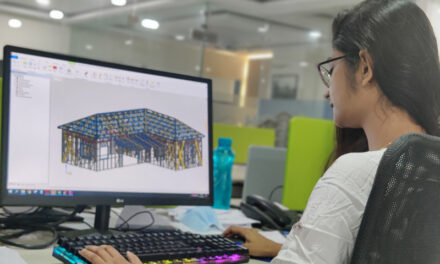

What will the brewery of the future look like? Will beer waste products automatically be turned into gasoline? Or will the work of the brewer soon be confined to the computer screen? Over the coming years, the growing importance of issues such as the cloud, data security, small batches, simulation tests, assignment and documentation will also continue to affect the way things work in the beer industry.

Digitalization enables fast adjustment to new market situations

Trend-conscious consumers rather than classical beer drinkers: Breweries are having to adjust to a changing market. This applies just as much to the big multinationals supporting a range of brands as it does to small craft breweries working to a wide variety of recipes. To have no choice but to expand their portfolio – economically and in line with stringent quality standards. Digitalization has a key role to play, creating the conditions for producers to respond with the necessary speed, flexibility and economy to the latest market demands, while maintaining a consistently high standard of quality. Because digitalization provides the transparency needed to efficiently manage the flood of data generated in breweries: from incoming deliveries

to dispatch, from the brewing kettle to management, from product development to the glass.

Digital Enterprise: The integrated approach to optimizing the entire value chain

The Digital Enterprise allows producing companies to achieve the end-to-end integration and digitalization of business processes – including their suppliers. They can begin at any point along the value chain from product design to servicing, and gradually expand the degree of digitalization depending on the company’s current needs. Siemens is on hand to support this process with its extensive brewing technology portfolio.

The Digital Enterprise allows producing companies to achieve the end-to-end integration and digitalization of business processes – including their suppliers. They can begin at any point along the value chain from product design to servicing, and gradually expand the degree of digitalization depending on the company’s current needs. Siemens is on hand to support this process with its extensive brewing technology portfolio.